Advanced Technology Institute

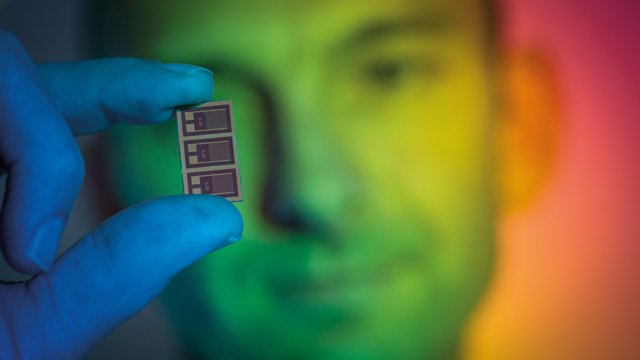

We are one of the University's world-leading research centres. We bring together researchers with an international outlook in quantum information, nanotechnology, energy and advanced materials.

ATI Newsletter Winter 2025

(772.1 KB .PDF)

What we have to offer

We have a wide range of facilities here which our members use to work on cross-cutting themes, addressing the “grand challenges” in energy, healthcare, information technology, sustainable technology and more generally, technologies associated with “quality of life”.

Study with us

Industry needs graduates with up-to-date skills and the ability to expand and develop their products. Industries engaged in nanotechnology and nanomaterials research and development are no different.

Meet our people

Professor Ravi Silva

Distinguished Professor, Interim Director - Institute for Sustainability (IfS), Director - Advanced Technology Institute (ATI) and Head of NanoElectronics Centre