Charlotte Foreman

About

Biography

Charlotte Foreman is an Associate Professor in the School of Engineering and Associate Dean Education for the Faculty of Engineering and Physical Sciences

Publications

This paper offers a perspective on 'care' as a component in the identity of successful university teachers. Three key lines of flight within this assemblage (care, pedagogic health, and salutogenesis) are examined here. In combination, they may offer a response to hegemonic neoliberal discourses that typically divert academics from enacting their professional values. A 'triple point' is hypothesised, at which the three lines would be found to co-exist, without border or barriers.

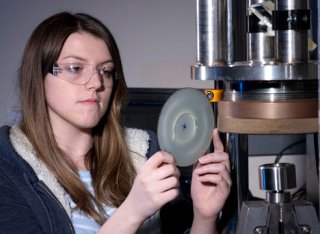

There has been extensive development in the offshore and marine industries of the use of polymer composite materials and understanding the durability of these materials is a significant challenge. Numerous test methods exist for the accelerated ageing of polymeric materials at the laboratory scale, but tests employing a combination of exposure conditions (e.g. at elevated temperature, under pressure, under a mechanical load) are lacking. In this work elevated temperatures are used to accelerate the ageing of polymer composite specimens when exposed to different combinations of immersion in water, pressure and mechanical loading. The results show that the behaviour of the material exposed to different combinations of exposure conditions, produces changes in residual properties (i.e. flexural modulus flexural strength and Tg) which are complex. Of immediate significance to understanding the behaviour of composites in a marine environment is the observation of a very significant decrease in the rate of moisture absorption for specimens tested under a pressure of 300 bar.

The use of 3D printers in higher education is becoming increasingly popular, with initiatives being reported in areas such as prototype development, design exploration and component/process visualisation. Diverse and cross-discipline applications in areas such as bio- and medical engineering, food processing and chemical product engineering are also rapidly emerging. The integration of 3D printers into engineering curricula is leading to an interest in pedagogy, and specifically innovative approaches to enhance teaching quality. The chapter provides an evaluation of such 3D printer use with discussion on future potential applications. The methodological approach has involved a literature review of current 3D printer uses in school and higher education contexts, an evaluation of the training requirements to enable wide accessibility of 3D printing, and stakeholder surveys and interviews.

Polymer composite materials are widely used in marine applications where an understanding of the long-term performance is essential for economic, safety and durability requirements. Although moisture absorption in composites has been studied for many years, the relationship between the mechanisms of moisture absorption and consequent changes in material behaviour has received much less attention. Understanding degradation is necessary for developing lifetime assessments. In this work, long-term exposure of a unidirectional carbon fibre epoxy composite material in water has been investigated in relation to mechanical property changes and moisture uptake. Using diffusion modelling and microscopy of the fracture surfaces, it is possible to correlate water absorption to experimental data showing how the position of water in the material causes changes to flexural properties (modulus decreased by 14% and strength by 20%) and in the glass transition temperature, T g reduced by 18%. Flexural modulus has been shown to be most affected by water interaction with the fibre interface; T g by water interaction within the resin; and flexural strength equally by water interaction with both fibre interface and resin.