Microstructural Studies Unit

Our MicroStructural Studies Unit (MSSU), the electron microscopy facility of the University of Surrey, was established in 1970 to support a wide range of research activities across the University and to offer electron microscopy services to industry.

Overview

After decades of continuous development, we employ experienced microscopists and house a comprehensive range of state-of-the-art instruments such as, scanning electron microscopes (SEM), X-ray microanalysis techniques, transmission electron microscope (TEM), hardness testing, optical microscopy, and sample preparation equipment.

Our unit is essential for a wide range of ongoing research projects and makes a significant contribution to undergraduate and postgraduate teaching. Research activities are numerous but presently include advanced metallurgical structures, materials ageing, perovskites, nanomaterials, thin films (including biofilms), novel inorganic materials, and more!

Collaboration

We work in close collaboration with the Surface Analysis Laboratory here at the University. A combination of state-of-the-art instrumentation, expertise in data interpretation and materials knowledge, enables experienced academics and technical staff to select the right combination of techniques for undertaking materials related research and development or solving technical problems.

We also work closely with our colleagues in the School of Chemistry and Chemical Engineering who can provide X-ray diffraction (XRD) alongside a range of spectroscopic techniques for materials analysis.

INDUSTRY. Such work includes product development, failure analysis, process problems, contaminant identification, verification of material composition and so forth.

Available instruments and services

Listed below are the instruments we have here in the MSSU. If you are interested in having a sample analysed, then please get in touch.

ThermoScientific Apreo Scanning-Transmission Electron Microscope (STEM)

The ThermoScientific Apreo FEG-STEM offers high-performance imaging and X-ray analysis. It can achieve a spatial resolution of about 1 nm. The chamber allows for larger specimens to be observed than older, more traditional SEMs. Due to developments in low-voltage imaging technology, the Apreo can image beam-sensitive materials at accelerating voltages as low as 200 Volts and a current of 1.6 pA. This allows for easy imaging of nanomaterials, plastics/polymers and beam-sensitive materials like perovskites.

With ThermoScientific ChemiSEM Technology – a unique live elemental imaging capability – EDS compositional information is always readily and quickly accessed through an easy-to-use interface. A range of external and in-lens detectors can display images simultaneously, giving excellent resolution across a wide range of accelerating voltage.

JEOL JSM-7100F Scanning Electron Microscope (SEM)

The JEOL JSM-7100F is a highly versatile, easy-to-use analytical field emission gun scanning electron microscope (FEG-SEM). It has a spatial resolution of 1.2 nm at 30 kV. The MSSU microscope is fitted with a ThermoScientific triple analysis system, featuring an UltraDry EDS detector, a MagnaRay parallel beam WDS spectrometer and a Lumis system for electron backscatter diffraction (EBSD).

All three analytical functions are integrated into a single ThermoScientific data system called Pathfinder to allow integration between these three complementary techniques.

ThermoScientific Talos 200i Transmission Electron Microscope (TEM)

The ThermoScientific Talos 200Fi is capable of both transmission (TEM) and scanning transmission (STEM) analysis. It is equipped with a high brightness FEG source (XFEG) and a high-resolution XTWIN lens, allowing single angstrom imaging resolution. Images are captured on a direct-electron detector camera (Ceta 16M, with up to 4k x 4k pixels) and smart acquisition routines, such as drift-compensated frame integration. In STEM mode, a Panther segmented STEM detector allows 5 simultaneous imaging modes, with complementary morphological and structural information about the sample. Elemental information can be mapped with nearly atomic resolution using a Dual X EDX system, which also designed for efficient collection during tomography.

Keyence VHX-7000 Digital Optical Microscope

Easy to use top-range digital optical microscope with variable magnification up to 4000x. Can be operated using reflected or transmitted light. Variety of segmented coaxial or ring lamp illumination with 3-axis stage movement to provide larger area high resolution tile scans and/or 3-D information. Polarising and Differential Image Contrast (DIC) options available. Post processing options for dimensional measurements, contamination/grain size/shape analysis. Surface topology, including waviness and roughness, can be investigated.

Cutting, mounting, grinding and polishing

The unit has cutting equipment to prepare specimens of various sizes and all material types with high degree of accuracy and minimising any heat affection. We have the ability to mount samples for analysis in epoxy resin, Bakelite thermoset plastic and acrylics.

The samples are then prepared using our modern grinding and polishing kit capable of preparation of metallics, ceramics, polymers, and minerals to a sub-micron finish. The techniques we employ include semi-automatic grinding and polishing on an array of abrasive clothes and discs. We have vibro-polishing which is perfect for improving EBSD pattern quality and more. All performed by highly trained metallographic preparation technical staff. We can also chemically etch for microstructural analysis.

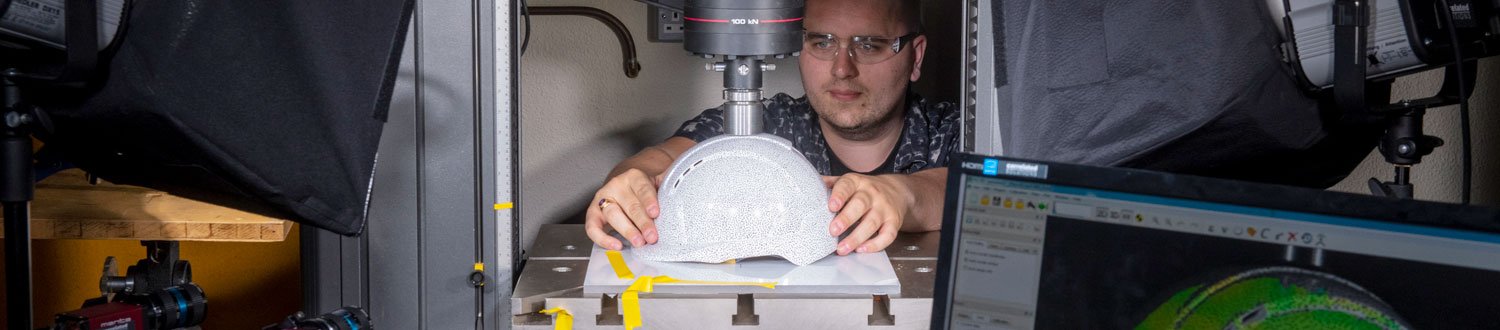

Hardness testing

We have a variety of hardness testing apparatus which can support industry clients in a range of applications from failure analysis to quality assurance testing. We have the capability to perform both macro and micro Vicker’s hardness testing, Knoop hardness testing, and Rockwell hardness testing.

Please talk to a member of the team if you want to discuss specific applied loads during testing.

The University can also provide other mechanical tests.

Find an expert

If you would like to use our services or instruments then please email our MSSU staff to discuss the work.

Dr Mark Baker

Professor of Surface Science and Engineering

James Whiting

MSSU Technician and Unit Manager

Research

Research within our Centre addresses ceramics, polymers and metals, as well as composite materials consisting of two or more of these materials, and explores a range of applications where such materials are being used to bring about improved performance or new products.