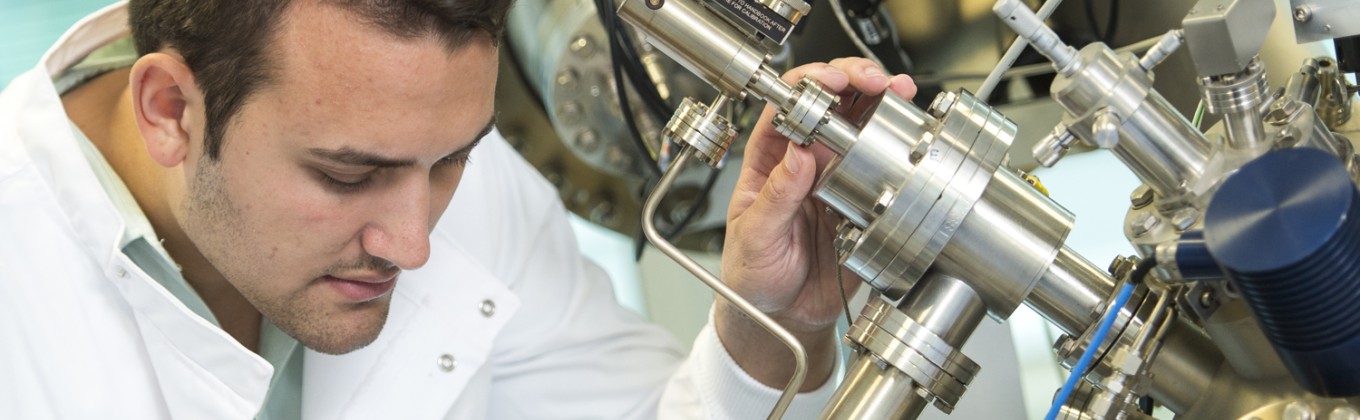

Surface Analysis Laboratory

Our laboratory contains the most complete cluster of surface analysis instrumentation for X-ray photoelectron spectroscopy (XPS), time-of-flight secondary ion mass spectrometry (ToF-SIMS), scanning auger microscopy (SAM) and scanning probe microscopy (SPM) in Europe.

Overview

The installed capital value of the instruments in our laboratory is of the order of £3 million and we have state-of-the-art instruments for scanning auger microscopy and X-ray photoelectron spectroscopy.

We work in close collaboration with the MicroStructural Studies Unit here at Surrey, an electron microscopy facility who employ experienced microscopists and have a wide range of state-of-the-art instruments.

Available instruments

Theta probe

A state-of-the-art small spot (15 µm) XPS instrument with a monochromated X-ray source and Ar ion gun for depth profiling. Excellent spatial resolution, sensitivity and energy resolution.

The instrument has parallel angle resolved XPS (PARXPS) capability enabling the acquisition of non-destructive depth profiles. The instrument now includes a preparation chamber which may be used for a range of in-situ and in-vacuo experiments and sample preparation procedures.

Microlab 350

A high spatial resolution (12 nm) Scanning Auger Microscope with simultaneous EDX analysis. XPS and BSE facilities are also available on this multi-technique instrument.

The instrument includes a preparation chamber which may be used for a range of in-situ and in-vacuo experiments and sample preparation procedures, including a fracture stage for metal and composite samples.

TOF.SIMS5

A high spatial and mass resolution ToF-SIMS instrument incorporating a polyatomic Bi ion source. Additional Cs and C60 ion sources are installed on this instrument as depth profiling etch sources although they may also be employed as analysis sources.

The instrument includes a preparation chamber which may be used for a range of in-situ and in-vacuo experiments and sample preparation procedures. In-situ stages for impact and controlled strain rate testing of materials are currently installed on the preparation chamber. The instrument also possesses heating and cooling stages in the entry lock and analysis chamber.

Scanning probe microscopy

The Laboratory has been active in SPM since 1992. Our equipment includes a Bruker Dimension Edge AFM system with PeakForce tapping mode and Kelvin Probe capabilities, the Nanoscope III (Multimode) for fundamental studies and in-situ electrochemical experiments, both in air and in liquids, and a MDT Solver with magnetic force microscopy (MFM) facilities as well as conventional AFM capable of being used under ambient or in-vacuo conditions.

ESCALAB Mk II

Standard, large area XPS instrument equipped with an XR4 twin anode X-ray source, an Alpha 110 analyzer and an Ar ion gun for sample etching. The instrument includes a sample preparation chamber which may be used for a range of in-situ and in-vacuo experiments and sample preparation procedures. UPS spectroscopy is also available on this instrument.

Find an expert

If you would like to use our services then please email our laboratory manager, Dr Steve Hinder to discuss your problem. Alternatively, join us on LinkedIn, questions and queries are welcome.

Dr Steven Hinder

Laboratory Manager

Dr Mark Baker

Professor of Surface Science and Engineering

Professor James Castle

Emeritus Professor of Materials

Professor John Watts

Professor of Materials Science

Research

Research within our Centre addresses ceramics, polymers and metals, as well as composite materials consisting of two or more of these materials, and explores a range of applications where such materials are being used to bring about improved performance or new products.