Sustainable Printing Applied Research Knowledge Laboratory

The Sustainable Printing Applied Research Knowledge laboratory - SPARKlab - focuses on the development of novel processing techniques for materials synthesis, printing and characterisation of functional nanomaterials and devices with applications in areas such as sensing, energy harvesting and environmental monitoring.

Overview

SPARKlab comprises a suite of equipment giving a concept-to-device capability for production of functional ceramic powders, ink formulation and printing. The emphasis of the work in the lab is on new materials and manufacturing technologies that could be used to create interactive devices that contain less harmful and sustainable materials with a secure supply.

Mission

Ceramic and metal structures are commonly manufactured using high temperatures and wasteful cutting operations. SPARKlab’s approach is to use low temperature additive techniques to build intricate structures which are not attainable using other methods. SPARKlab specialises in:

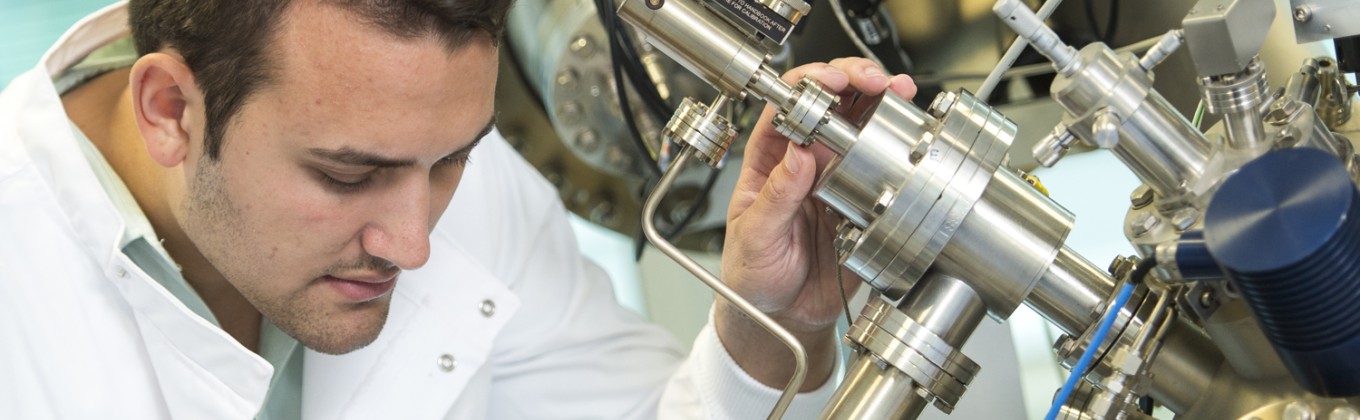

- Formulation, printing and processing of advanced functional materials and devices

- Electrical characterisation, including resistance, impedance, capacitance, voltage and current

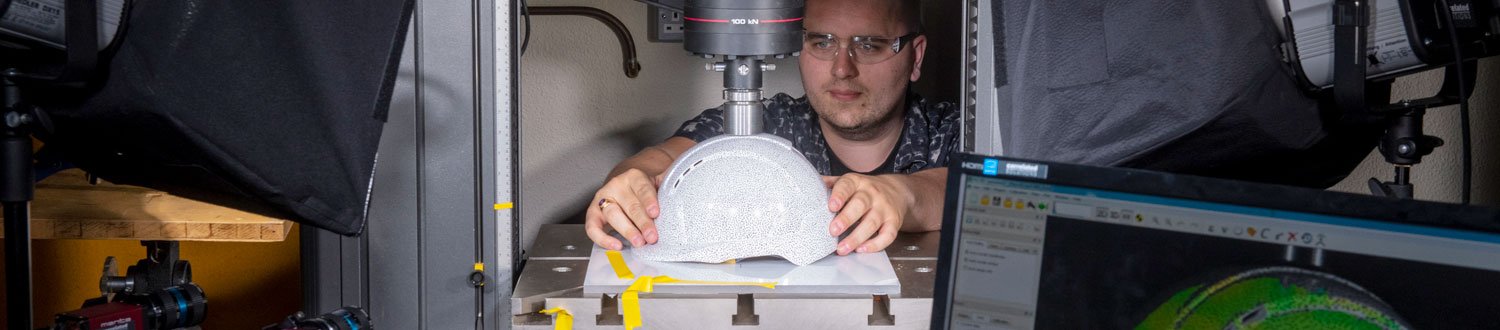

- Physical characterisation including microstructural analysis, mechanical testing and device performance.

Explore our facilities

Watch our videos showing the scanned laser systems for sintering of ceramic films and an exploded view of it.

Our Centre also offers comprehensive microscopy facilities with the Microstructural Studies Unit and Surface Analysis Laboratory.

Get in contact

If you are interested in finding out more about our laboratory, or have a query then please get in touch.

Professor Robert Dorey

Professor of Nanomaterials

Research

Research within our Centre addresses ceramics, polymers and metals, as well as composite materials consisting of two or more of these materials, and explores a range of applications where such materials are being used to bring about improved performance or new products.