Professor Jin Xuan

Academic and research departments

Faculty of Engineering and Physical Sciences, School of Chemistry and Chemical Engineering.About

Biography

Professor Jin Xuan joined the University of Surrey as the Associate Dean of Research and Innovation for the Faculty of Engineering and Physical Sciences in September 2022. He holds a Chair in Sustainable Processes and a prestigious EPSRC Open Fellowship at the School of Chemistry and Chemical Engineering. He is also a Turing Fellow at The Alan Turing Institute. Before moving to Surrey, he was the Head of the Department of Chemical Engineering at Loughborough University.

Professor Xuan has won a number of prizes and awards in recognition of his research excellence. He is the recipient of the Philip Leverhulme Prize of Engineering in 2022 for his pioneering research on Energy and AI, the Beilby Medal and Prize, jointly from the Society of Chemical Industry (SCI), the Royal Society of Chemistry (RSC), and the Institute of Materials, Minerals and Mining (IOM3) in 2020 for his work that ‘has exceptional practical significance in chemical engineering, applied materials science, energy efficiency or a related field’, and the International Association for Green Energy (IAGE) Technology Innovation Award in 2025 for "pioneering innovative electrochemical techniques exemplifying the principle of circular economy, while promoting environmental sustainability and economic growth". He led the UKRI CircularChem Centre winning the IChemE Global Award for Sustainability in 2023 and the RSC Environment, Sustainability and Energy Horizon Prize: John Jeyes Prize in 2025. He led the Surrey team being part of the Flue2Chem project, named as the UK National Winner of the 2025 Net-Zero Industries Award, announced at COP30.

Professor Jin Xuan is a recognised leader in enterprise and commercialisation, with a strong track record of translating academic innovation into real-world impact. He is the Co-founder and Chief Technology Officer of R3V Tech, developing next-generation circular economy technologies for the chemicals and fuels industries. Under his leadership, R3V Tech has received more than half million GBP funding and been selected for the Shell StartUp Engine and the Royal Society of Chemistry CleanTech Accelerator Cohort. More recently, Professor Xuan also serves as the Principal Academic Advisor to EcoShift.AI, applying artificial intelligence to optimise industrial decarbonisation.

Professor Xuan actively takes leadership in the wider research community. He is an EPSRC Strategic Advisory Team (SAT) member for Energy and Decarbonisation, and a member of the Research, Innovation & Knowledge Transfer Committee of the Engineering Professors’ Council.

Prof Xuan contributed to the establishment of the emerging Energy and AI research community globally. He is the Founding Editor-in-Chief of Digital Chemical Engineering (IChemE), the Founding Editor of Energy and AI (Elsevier), and the co-chair of the International Conference of Energy and AI series (Tianjin 2020, London 2021, Belfort 2022, Xining 2023, Ningbo 2024, Reykjavik 2025). In his Editorial of Energy and AI, he provided a strategic overview in this interdisciplinary research area including wider societal issues such as ethics, morality, policy and law.

Professor Xuan is an advocate for Responsible Assessment. He was interviewed by Nature as part of a news item China bans cash rewards for publishing papers, where he provided his expert view on policy development for proper use of journal metrics in research evaluation. He also actively promotes EDI in the wider research community. He serves as a member of the EPSRC's EDI Strategic Advisory Group and the EDI Champion in the EPSRC Energy SAT. He is the leading author of The equality, diversity and inclusion in energy and AI: Call for actions.

University roles and responsibilities

- Associate Dean (Research and Innovation) for the Faculty of Engineering and Physical Sciences

- Professor of Sustainable Processes

- Member of Council

- Member of Senate

- Member of the Faculty EDI Committee

News

ResearchResearch interests

Professor Xuan’s research focuses on net zero energy, circular economy and sustainable development via digital and engineering innovations. He is leading the development of bespoke AI and digital solutions to enable next generation energy and chemical materials, devices, processes and systems. His research has significantly influenced the early development of Energy and AI as a young, interdisciplinary field internationally.

The future sustainable development of novel energy generation and materials manufacturing relies on radical innovations in chemical processes with highly embedded functionality, integration and multi-physics interactions. Prof Xuan has led the development of novel multiscale predictive models beyond the state of art for complex chemical and energy systems, and has delivered affordable, inclusive low-carbon solutions to tackle global climate change challenges. His work on advanced modelling has influenced the fundamental understanding of complex flow and chemical systems, by having discovered a number of important reaction/fluid phenomena at microscale, and has impacted on the development of a series of energy devices, such as fuel cells, electrolysers and solar fuel reactors.

His current research is focusing on the digital transformation of complex chemical and energy processes via integrated smart sensing, advanced modelling and data-centric deep learning, with a vision to deliver a paradigm-shift in how future materials, processes and systems can be designed, optimised and self-evolved throughout their entire lifecycle, enabling connected products and services, and making them super-efficient, zero-loss, whilst maximising their value creation.

Circular Chemical Economy

Prof Xuan is the Director of the £4.5 million UKRI Interdisciplinary Centre for Circular Chemical Economy. It brings together stakeholders from academia, industry, government, NGOs and general public to transform the UK’s chemical industry into a fossil-independent, climate-positive and environmentally-friendly circular economy. The Centre is playing a key role in helping the UK to reduce waste and the environmental impacts of production and consumption and creating opportunities for new UK industries, which has been recognised as the winner of the IChemE Global Award for Sustainability 2023 and the RSC Environment, Sustainability and Energy Horizon Prize: John Jeyes Prize 2025.

EPSRC Open Fellowship

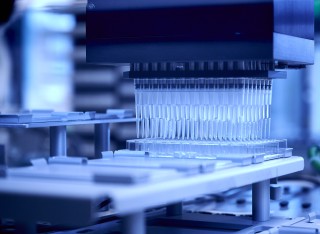

Prof Xuan holds a prestigious EPSRC Open Fellowship to develop the next generation of clean energy devices using advanced artificial intelligence (AI). The five-year £2 million fellowship will enable Prof Xuan to develop novel explainable AI (XAI) tools and models which lead to an automated loop of materials design, manufacturing and testing of electrochemical materials and devices. Prof Xuan will work with industrial partners from Siemens PSE, Intelligent Energy and Johnson Matthey.

Flue2Chem:

Building a UK value chain in converting industrial waste gases into sustainable materials for consumer products

Prof Xuan is leading the Surrey team as part of the Flue2Chem project, which is a £5.4m, two-year, Innovate UK programme spearheaded by Unilever. In the project, industry giants in the UK are joining forces in the first-ever cross-sector collaboration aimed at reducing greenhouse gas emissions, with the aims to convert industrial waste gases into chemicals that can be used to manufacture superior and more sustainable consumer products. The Flue2Chem Project is featured as a case study in the UK government's Advanced Manufacturing Plan, released in December 2023. The project has been named the UK National Winner of the 2025 Net-Zero Industries Award, announced at COP30.

Research interests

Professor Xuan’s research focuses on net zero energy, circular economy and sustainable development via digital and engineering innovations. He is leading the development of bespoke AI and digital solutions to enable next generation energy and chemical materials, devices, processes and systems. His research has significantly influenced the early development of Energy and AI as a young, interdisciplinary field internationally.

The future sustainable development of novel energy generation and materials manufacturing relies on radical innovations in chemical processes with highly embedded functionality, integration and multi-physics interactions. Prof Xuan has led the development of novel multiscale predictive models beyond the state of art for complex chemical and energy systems, and has delivered affordable, inclusive low-carbon solutions to tackle global climate change challenges. His work on advanced modelling has influenced the fundamental understanding of complex flow and chemical systems, by having discovered a number of important reaction/fluid phenomena at microscale, and has impacted on the development of a series of energy devices, such as fuel cells, electrolysers and solar fuel reactors.

His current research is focusing on the digital transformation of complex chemical and energy processes via integrated smart sensing, advanced modelling and data-centric deep learning, with a vision to deliver a paradigm-shift in how future materials, processes and systems can be designed, optimised and self-evolved throughout their entire lifecycle, enabling connected products and services, and making them super-efficient, zero-loss, whilst maximising their value creation.

Circular Chemical Economy

Prof Xuan is the Director of the £4.5 million UKRI Interdisciplinary Centre for Circular Chemical Economy. It brings together stakeholders from academia, industry, government, NGOs and general public to transform the UK’s chemical industry into a fossil-independent, climate-positive and environmentally-friendly circular economy. The Centre is playing a key role in helping the UK to reduce waste and the environmental impacts of production and consumption and creating opportunities for new UK industries, which has been recognised as the winner of the IChemE Global Award for Sustainability 2023 and the RSC Environment, Sustainability and Energy Horizon Prize: John Jeyes Prize 2025.

EPSRC Open Fellowship

Prof Xuan holds a prestigious EPSRC Open Fellowship to develop the next generation of clean energy devices using advanced artificial intelligence (AI). The five-year £2 million fellowship will enable Prof Xuan to develop novel explainable AI (XAI) tools and models which lead to an automated loop of materials design, manufacturing and testing of electrochemical materials and devices. Prof Xuan will work with industrial partners from Siemens PSE, Intelligent Energy and Johnson Matthey.

Flue2Chem:

Building a UK value chain in converting industrial waste gases into sustainable materials for consumer products

Prof Xuan is leading the Surrey team as part of the Flue2Chem project, which is a £5.4m, two-year, Innovate UK programme spearheaded by Unilever. In the project, industry giants in the UK are joining forces in the first-ever cross-sector collaboration aimed at reducing greenhouse gas emissions, with the aims to convert industrial waste gases into chemicals that can be used to manufacture superior and more sustainable consumer products. The Flue2Chem Project is featured as a case study in the UK government's Advanced Manufacturing Plan, released in December 2023. The project has been named the UK National Winner of the 2025 Net-Zero Industries Award, announced at COP30.

Publications

Highlights

Recent representative publications

- Jiao K, Xuan J, Du Q, Bao Z, Xie B, Wang B, Zhao Y, Fan L, Wang H, Hou Z, Huo S, Brandon NP, Yin Y, Guiver MD, Designing the next-generation of proton exchange membrane fuel cells, Nature, 2021, 595, 361-369

- Niu Z, Pinfield VJ, Wu B, Wang H, Jiao K, Leung DYC, Xuan J*, Towards the digitalisation of porous energy materials: Evolution of digital approaches for microstructural design, Energy & Environmental Science, 2021, 14, 2549-2576. (Highlighted as journal front cover)

- Niu Z, Zhao W, Wu B, Wang H, Lin W, Pinfield VJ, Xuan J*, π Learning: A Performance-informed framework for microstructural electrode design, Advanced Energy Materials, 2023, 13, 2300244. (Highlighted as journal front cover)

- Leong KW, Pan W, Yi X, Luo S, Zhao X, Zhang Y, Wang Y, Mao J, Chen Y, Xuan J, Wang H, Leung DYC, Next-generation magnesium-ion batteries: The quasi-solid-state approach to multivalent metal ion storage, Science Advances, 2023, 9, eadh1181.

- Pan W, Zhao Y, Mao J, Wang Y, Zhao X, Leung KW, Luo S, Liu X, Wang H, Xuan J, Yang S, Chen Y, Leung DYC, High-energy single-walled carbon nanotube cathode for aqueous Al-ion battery boosted by multi-ion intercalation chemistry, Advanced Energy Materials, 2021, 11, 2101514. (Highlighted as journal back cover)

- Wang B, Zhang G, Wang H, Xuan J*, Jiao K, Multi-physics-resolved digital twining of proton exchange membrane fuel cells with a data-driven surrogate model, Energy and AI, 2020, 1, 100004.

- Lu X, Zhu C, Wu Z, Xuan J, Francisco JS, Wang H, In-situ observation of the pH gradient near the gas diffusion electrode of CO2 reduction in alkaline electrolyte, Journal of the American Chemical Society, 2020, 142, 15438–15444. (Highlighted as journal front cover)

- Xu H, Ma J, Tan P, Chen B, Wu Z, Zhang Y, Xuan J*, Ni M, Towards online optimisation of solid oxide fuel cell performance: combining deep learning with multi-physics simulation, Energy and AI, 2020, 1, 100003.

- Zhakeyev A, Wang P, Zhang L, Shu W, Wang H, Xuan J*, Additive manufacturing: Unlocking the evolution of energy materials, Advanced Science, 2017, 4, 1700187. (Most Accessed Article in November 2017)

- Wang B, Prinsen P, Wang H, Bai Z, Wang H, Luque R, Xuan J*, Macroporous materials: microfluidic production, functionalization and application, Chemical Society Reviews, 2017, 46, 855-914.

The electrochemical conversion of biomass-derived compounds into value-added chemicals using renewable electricity has attracted attention as a promising pathway for sustainable chemical production, with the electrooxidation of cyclohexanol being a typical example. However, optimizing and upscaling these processes have been hindered due to a limited understanding of the underlying mechanisms and limiting factors. To address this, there is a critical need for experimental tools that enable more efficient and reproducible measurements of these complex processes. In this work, we develop an automated microfluidic platform and use it to conduct controlled and efficient measurements of cyclohexanol electrooxidation on nickel electrodes under various electrolyte compositions and flow rates. The platform features microchannel networks integrated with multiple analytical instruments such as pumps, an electrochemical workstation, and a digital microscope to perform laboratory functions including electrolyte preparation, reaction control, microscopy, and electrochemical characterization, all streamlined through automation. Cyclohexanol electrooxidation on nickel is found to follow Fleischmann's mechanism, with an irreversible heterogeneous reaction as the rate-determining step. The effects of ionic and nonionic surfactant additives are screened, both demonstrating the ability to enhance current densities through different mechanisms. The developed platform is readily transferable for measuring other power-to-chemical processes and is believed to be a powerful tool for accelerating the understanding and development of sustainable electrosynthesis.

Generative Artificial Intelligence is a rapidly developing area being used to create powerful tools which have the potential to change a wide range of professional practices in chemical engineering. As this area develops, new principles on responsible use of Generative AI in chemical engineering are required to ensure that traditional engineering ethics are able to accommodate the new landscape. In this perspective, we assess the current state of engineering ethics, responsible AI principles and suggest how they can combine to ensure that Generative AI can be used responsibly within the chemical engineering sector. Whilst there are many aspect to engineering ethics and responsible AI use, the core principles which include transparency, integrity, and accountability are omnipresent and provide a shared foundation of good practice on which new regulations may be built as the need arises. Future breakthrough will require development on the AI technology itself, the people-centre approach and regulation changes.

This novel study presents an effective comprehensive life cycle assessment (LCA) of a novel sustainable carbon dioxide capture and utilization (CCU) system to co-produce alcohol ethoxylate (AE7), a valuable surfactant (a high-value chemical component of liquid detergents), and low-medium distillate range liquid fuel. Conventionally, AE7 is produced by reacting fatty alcohols with ethylene oxide from mostly fossil and marginally bio-based resources. This research develops novel AE7 production using carbon sources from flue gas of paper and steel industries, addressing a critical gap in the literature. The core process is Fischer-Tropsch (FT) synthesis using syngas formed by the reverse-water-gas-shift reaction, where recycled CO2 reacts with H2. FT produces C11-C13 alkanes and a light-to-medium fuel co-product. The alkanes are converted into C12-C14 fatty alcohols through dehydrogenation, hydroformylation, and hydrogenation. Fatty alcohols react with ethylene oxide to form AE7. The yields (w/w) of AE7 and the fuel co-products are 3.7 % and 3.4 % for paper industry flue gas, and 8.0 % and 9.5 % for steel industry flue gas, respectively. Renewable (wind) electricity meets the hydrogen demand and electricity needs for the reactions, a total of 13.4 and 33.3 kWh/kg flue gas, respectively. The life cycle impact assessment includes global warming potential (GWP) and other impacts using ReCiPe, Impact+ , and Product Environmental Footprint methods. Baseline scenarios show GWP ranging from 2.2 to 3.6 kg CO2e/kg surfactant for conventional cradle-to-gate AE production systems. The new systems have GWP ranging 0.4–1.3 kg CO2e/kg flue gas (cradle-to-gate) using mass allocation. Meanwhile, the paper industry’s flue gas system has biogenic CO2, while the steel industry’s CO2 is fossil-based. Considering the GWP reductions due to biogenic CO2 contents, their overall GWP is 2.56 kg CO2e and 10.33 kg CO2e per kg of product (AE7 +fuel) (cradle-to-grave) using economic allocation. Thus, biogenic CCU is critical for the sustainable co-production of high-value surfactants and fuel.

In order to utilize different wavelengths of rays in the solar spectrum and improve the power generation efficiency of solar systems, a novel linear Fresnel solar CPV/T hybrid system with advanced film beam splitter is proposed in this study. The system mainly consists of a Linear Fresnel Reflector (LFR) concentrator, the PV utilization sub-system, the thermal utilization sub-system, and the film beam splitter, where the thermal utilization sub-system includes a thermal receiver tube and a matching secondary reflector. The film beam splitter is designed by using the Needle method, and the average reflectance and transmittance of the film beam splitter are 26.43% and 73.57% under the full solar spectrum, respectively. The optical performance and thermodynamic analysis of the system are conducted through Monte Carlo Ray Tracing (MCRT) and Computational Fluid Dynamics (CFD) simulation methods. The optical performance results show that the concentrator can provide relatively high concentrating uniformity and the optimal installation height of the thermal receiver tube is about 1446.0 mm. The overall optical efficiency of the novel linear Fresnel solar CPV/T hybrid system can be maintained above 90% when the incident deviation angle is controlled to be within 0.1°. The thermodynamic analysis results indicate that utilizing water at 10 bar as the internal heat transfer medium (HTM) within the thermal receiver tube can effectively enhance the system’s thermal performance through the strategic reduction of the operating temperature of the solar cells and the inlet HTM temperature of the thermal receiver tube, coupled with an increase in the inlet HTM velocity. At the operating temperature of solar cells of 303.0 K, the inlet HTM temperature of 293.0 K and the velocity of the thermal receiver tube of 0.005 m s-1, respectively, the system attains a total output power of 7146.3 W and an exergy efficiency of 25.98%. [Display omitted] •A novel linear Fresnel solar CPV/T hybrid system based on film beam splitter is proposed.•Various designs of the film beam splitter on silicon CPV cell performance are studied.•Reflectance and transmittance of the film beam splitter are used as performance indicators.•The CPV/T hybrid system achieves improved concentrating uniformity.•The total output power and exergy efficiency attain 7146.3 W and 25.98%, respectively.

•Novel TEA of AE7 surfactant production using CO2 from steel industry flue gas•CO2 conversion rates around 3% in different processing capacities•Green hydrogen costs are the biggest factor influencing minimum selling price (MSP)•Lowest MSP of $8.77/kg exceeds the forecasted $3.75/kg for fossil-based AE7•Monte Carlo simulation shows a 21% chance of positive NPV vs. bio-based surfactants Successfully transitioning to a net-zero and circular carbon economy requires adopting innovative technologies and business models to capture CO2 and convert it into valuable chemicals and materials. Given the high economic costs and limited funding available for this transition, robust economic modelling of potential circular carbon pathways is essential to identify economically viable routes. This study introduces a novel techno-economic analysis (TEA) of producing alcohol ethoxylate (AE7), a valuable surfactant, from industrial flue gas. Traditionally, AE7 is produced by reacting fatty alcohols with ethylene oxide derived from fossil or bio-based sources. This research explores a method using CO2 captured from steel industry flue gas to produce AE7, addressing a notable gap in the literature. It evaluates a thermo-catalytic pathway involving Fischer-Tropsch (FT) synthesis with syngas generated by the reverse-water gas-shift reaction, where CO2 reacts with H2. CO2 conversion rates range around 3% across processing capacities of 25 kt/a, 100 kt/a, and 1000 kt/a. The study finds that the CO2 mass fraction concentration in the process emission is 2.47 × 10–5, compared to 0.13 in the incoming flue gas, highlighting the system's positive environmental impact. A radial basis function neural network was built to forecast the long-term average price of fossil-based and bio-based surfactants to benchmark the results against. Economic analysis reveals that the cost of green hydrogen significantly impacts the minimum selling price (MSP), making cost parity with existing fossil-based surfactants challenging. The lowest MSP of $8.77/kg remains above the long-term forecasted price of $3.75/kg for fossil-based C12–14 AE7. However, Monte Carlo simulations show a 21% probability of achieving a positive net present value (NPV) compared to leading bio-based surfactant alternatives. Sensitivity analyses identify capital costs, the price of low-carbon hydrogen (LCOH), and diesel prices as the most influential factors affecting the MSP. Continued advancements in Fischer-Tropsch catalyst technologies, reductions in green hydrogen costs and growing consumer demand for environmentally friendly products could significantly enhance the economic feasibility of this sustainable approach, paving the way for broader adoption and contributing to a circular carbon economy. [Display omitted]

Designing high‐performance porous electrodes is the key to next‐generation electrochemical energy devices. Current machine‐learning‐based electrode design strategies are mainly orientated toward physical properties; however, the electrochemical performance is the ultimate design objective. Performance‐orientated electrode design is challenging because the current data driven approaches do not accurately extract high‐dimensional features in complex multiphase microstructures. Herein, this work reports a novel performance‐informed deep learning framework, termed π learning, which enables performance‐informed microstructure generation, toward overall performance prediction of candidate electrodes by adding most relevant physical features into the learning process. This is achieved by integrating physics‐informed generative adversarial neural networks (GANs) with convolutional neural networks (CNNs) and with advanced multi‐physics, multi‐scale modeling of 3D porous electrodes. This work demonstrates the advantages of π learning by employing two popular design philosophies: forward and inverse designs, for the design of solid oxide fuel cells electrodes. π learning thus has the potential to unlock performance‐driven learning in the design of next generation porous electrodes for advanced electrochemical energy devices such as fuel cells and batteries. An innovative performance‐informed deep learning framework is demonstrated for microstructural fuel cell electrode design. The framework is applied to two popular electrode design philosophies; forward and inverse design, demonstrating its versatility and robustness. This work paves an efficient way for designing novel electrode microstructures with direct performance evaluation for advanced electrochemical energy devices beyond fuel cells.

Sludge conditioning by the Fenton process can effectively reduce sludge water content. The Fenton process has ideal dewaterability at different initial pH levels. However, the difference in the initial pH levels can lead to variations in conditioner dosage, resulting in different environmental impacts and economic pressures. This study provides insights into the role of the life cycle linked response surface methodology (LC-RSM) framework in revealing optimal solutions with both environmental and economic performance in different combinations of conditioners. Response surface methodology (RSM) was used to construct a model of sludge dewatering by the Fenton process, and life cycle assessment and life cycle cost were used to quantify the environmental and economic performance of all conditioning solutions in the model. The LC-RSM optimization solution was 6%–68% and 15%–70% lower than the RSM recommended solution in terms of environmental impacts and economic costs, respectively. For specific impact categories, such as global warming potential, the LC-RSM optimization solution was 19%–56% lower than the RSM recommended solution. In addition, the total environmental impact of the different conditioner combinations ranged between 4.1 and 7.8 Pt and 3.2–6.7 Pt at 53% and 58% of the sludge target water content, respectively. Surprisingly, the environmental impact of the solution with superior dewatering performance (53%) was lower than that of the solution with poor dewatering performance (58%) in many cases. The above results show that the LC-RSM optimization solution has better environmental and economic performance compared to RSM. In addition, the environmental impacts and economic costs of different solutions with the same water content target vary widely, which may lead to comparing sludge conditioning procedures with different targets in an unfair environment. Therefore, a unified platform for comparison is needed, and LC-RSM can provide support. This study can assist decision-makers in identifying the best solution for both environmental and economic performance in a multivariate system and stimulate further discussion on how to compare different processes on a more uniform platform.

The drive for efficiency improvements in CO2 capture technologies continues to grow, with increasing importance given to the need for flexible operation to adapt to the strong fluctuations in the CO2-rich flue gas flow rate and CO2 concentration. Using renewable energy can improve the environmental benefit of CO2 capture technologies; however, renewable energy resources often suffer from the challenge of non-uniform power generation as a result of weather and seasonal variations. In this work, we aimed to dynamically self-optimise the CO2 capture process in a renewable energy system via enhanced weathering of calcite with fresh water in a packed bubble column (PBC) reactor, in which CO2 from flue gas produced by a power plant is converted into bicarbonate and stored in the ocean. Data-driven surrogate dynamic models of the PBC reactor are developed to predict the reactor CO2 capture rate (CR) and power consumption (PC) and are trained using the data generated by physics-based models. Two deep learning models are considered to capture the dynamics of the PBC reactor: a long short-term memory network (LSTM); and a two-stage multilayer perceptron network (MLP). Data-driven models based on LSTM were developed to predict wind energy (R2: 0.908) and inlet flue gas CO2 concentration (R2: 0.981) using publicly available datasets. A multi-objective NSGA-II genetic algorithm is then applied that utilised the inlet flue gas CO2 concentration and wind energy predictions to pre-emptively self-optimise the reactor process conditions (i.e., superficial liquid flow rate and superficial gas flow rate) to maximise the carbon capture rate and minimise non-renewable energy consumption. The results should that by using the dynamic modelling and predictive multi-objective optimisation framework proposed within this study, the PCB reactor CR increased by an average of 16.7% over a one-month operation, whilst simultaneously reducing the proportion of now-renewable energy consumed from an average of 92.9% to an average of 56.6%. Overall, this study demonstrates the effectiveness of a dynamic data-driven modelling and multi-objective optimisation approach to increase the operational flexibility of CO2 capture reactors to adapt to strong fluctuations in flue gas and intermittent renewable energy supply.

•Linear Fresnel solar collector is designed using enhancer.•Heat transfer and flow characteristics with various enhancers are studied.•Lower rotation rate benefits the enhanced performance of Kenics mixer insert.•Overall optimum case achieves PEC value ranging 1.47∼1.73 compared to plain case. Linear Fresnel collector system is a type of solar thermal utilization installation. It is mainly used to focus solar radiation on the receiver tube to generate high temperature thermal energy which can be applied in many aspects. This study investigates five different types of receiver tube models using water as the flowing medium, which leads to improving heat transfer performance by means of being equipped with enhancers. The optical results and thermohydraulic performance of the Linear Fresnel collector system are evaluated through Monte Carlo Ray Tracing and Computational Fluid Dynamics (CFD) simulation methods. The obtained optical results reveal that the distribution of energy flux density concentrating on the receiver tube surpasses that of the parabolic trough collector system. In order to maintain an energy reception rate of 90.0% or higher, the installation height range of the receiver tube should be between 1468–1532 mm. When the sun-tracking error increases from 0.0° to 1.0°, the overall optical efficiency of the Linear Fresnel collector system decreases from 98.9% to 79.7%. The thermohydraulic performance shows that the enhancers can generate a swirling flow as its main feature, which effectively promotes the homogenization of the temperature field and destroys the boundary layer near the receiver tube wall, thus greatly improving the convective heat transfer in the receiver tube. However, the introduction of the enhancers also means that the pressure drop loss of the receiver tube increases. Furthermore, the impact of the Kenics mixer's enhancer on heat transfer and flow characteristics is further amplified as the rotation rate decreases, owing to its alternating and complex structure. Through a comparative analysis of the influence of different receiver tube models on Nusselt number (Nu), Frictional resistance coefficient (f) and comprehensive evaluation criterion (PEC) under four rotation rate conditions (y = 6.3, 8.1, 11.34, 18.9), the conclusions present that the receiver tube with an enhancer at a low rotation rate has a larger Nu than that at a high rotation rate, while the Frictional resistance coefficient changes little at different rotation rates. Therefore, the PEC is higher when the receiver tube is equipped with a low-rotation-rate enhancer. Moreover, the receiver tube equipped with a Kenics mixer at a rotation rate of 6.3 was found to be the overall optimum case, with the PEC value varying from 1.47 to 1.73. [Display omitted]

Green hydrogen from water electrolysis is a key driver for energy and industrial decarbonization. The prediction of the future green hydrogen cost reduction is required for investment and policy-making purposes but is complicated due to a lack of data, incomplete accounting for costs, and difficulty justifying trend predictions. A new AI-assisted data-driven prediction model is developed for an in-depth analysis of the current and future levelized costs of green hydrogen, driven by both progressive and disruptive innovations. The model uses natural language processing to gather data and generate trends for the technological development of key aspects of electrolyzer technology. Through an uncertainty analysis, green hydrogen costs have been shown to likely reach the key target of

Proton exchange membrane (PEM) based electrochemical systems have the capability to operate in fuel cell (PEMFC) and water electrolyser (PEMWE) modes, enabling efficient hydrogen energy utilisation and green hydrogen production. In addition to the essential cell stacks, the system of PEMFC or PEMWE consists of four sub-systems for managing gas supply, power, thermal, and water, respectively. Due to the system's complexity, even a small fluctuation in a certain sub-system can result in an unexpected response, leading to a reduced performance and stability. To improve the system's robustness and responsiveness, considerable efforts have been dedicated to developing advanced control strategies. This paper comprehensively reviews various control strategies proposed in literature, revealing that traditional control methods are widely employed in PEMFC and PEMWE due to their simplicity, yet they suffer from limitations in accuracy. Conversely, advanced control methods offer high accuracy but are hindered by poor dynamic performance. This paper highlights the recent advancements in control strategies incorporating machine learning algorithms. Additionally, the paper provides a perspective on the future development of control strategies, suggesting that hybrid control methods should be used for future research to leverage the strength of both sides. Notably, it emphasises the role of artificial intelligence (AI) in advancing control strategies, demonstrating its significant potential in facilitating the transition from automation to autonomy.

This paper reports the first theoretical modeling study of air-breathing microfluidic fuel cells (MFCs). The model is based on a semi-empirical Graetz–Damköhler (Gz–Da) analysis. The theoretical formulas derived clearly demonstrate the effects of the MFC design and operational parameters on the electrochemical activities of MFCs in quantitative detail. The modeling analysis shows that the electrode kinetics have significant effects on the trade-off relationship between the fuel utilization and current density. Moreover, the analysis reveals that the co-laminar flow of MFCs limits the fuel utilization considerably. ► A theoretical model of air-breathing microfluidic fuel cells (MFC) is reported. ► Pe–Da analysis for MFC is performed. ► Electrode kinetics is important for fuel utilization–current relationship. ► Co-laminar flow of MFC is largely the limiting factor causing low fuel utilization.

Nickel-yttrium stabilized zirconium (Ni-YSZ) nanocomposite were synthesized by to different paths: mechanochemical method and a novel sol-gel method at different temperatures. Preliminary structural/textural results obtained by XRD, BET and SEM analyses showed a typical crystalline cubic structure, with small crystallite size in those nanocomposites synthesized by sol-gel method as well as higher specific surface area and uniform distribution. (C) 2017 The Authors. Published by Elsevier Ltd.

Graphene microspheres are fabricated through a 3D-printed inkjet nozzle based on the gas-liquid microfluidic method. This method realizes rapid and controllable fabrication of uniform graphene microspheres with up to 800 mu L min(-1) (ca. 1 L d(-1)) of yields, which is 2 orders of magnitude higher than those of the conventional microfluidic method. The diameter of the graphene microspheres could be flexibly controlled from 0.5 to 3.5 mm by adjusting the gas pressure. The porous graphene microspheres show great dye decoloration performance. The maximum adsorption capacity of methylene blue is 596 mg/g, which is the highest adsorption capacity among that of the reduced graphene-oxide absorbents. A performance improvement of 21% is obtained by applying sodium alginate into graphene as a curing agent. The adsorption behavior follows a Langmuir isotherm and pseudo-second-order kinetic model. Besides, the graphene microspheres exhibit great selective adsorption and could separate cationic dye methylene blue (MB) and anionic dye methyl orange (MO).

Energy storage capacity has been a major limiting factor in pursuit of increasing functionality and mobility for portable devices. To increase capacity limits, novel battery designs with multi-electron redox couples and increased voltages have been listed as a priority research direction by the US Department of Energy. This study leverages the benefits of microfluidics technology to develop a novel mixed-pH media aluminum-air cell which incorporates the advantages of the trivalence of aluminum and mixed-pH thermodynamics. Experimentally, the new cell exhibited an open circuit potential of 2.2 V and a maximum power density of 176 mW cm(-2), which are respectively 37.5% and 104.6% higher than conventional single alkaline aluminum-air cell under similar conditions. With further optimization of channel thickness, a power density of 216 mW cm(-2) was achieved in the present study. (C) 2015 Elsevier Ltd. All rights reserved.

Energy storage and conversion is a very important link between the steps of energy production and energy consumption. Traditional fossil fuels are natural and unsustainable energy storage medium with limited reserves and notorious pollution problems, therefore demanding for a better choice to store and utilize the green and renewable energies in the future. Unitized regenerative fuel cell (URFC), a compact version of regenerative fuel cell with only one electrochemical cell, is one of the competent technologies for this purpose. A URFC can produce hydrogen fuel through an electrolysis mode to store the excess energy, and output power in a fuel cell mode to meet different consumption requirements. Such a reversible system possesses several distinctive advantages such as high specific energy, pollution-free, and most importantly, the decoupled energy storage capacity with rated power. Based on the different electrolytes utilized, current available URFC technologies include the most common proton exchange membrane (PEM)-based URFC, and other types of URFC such as the alkaline, solid oxide and microfluidic URFCs. This part of the URFC review emphasizes on the PEM-based URFC. Specifically, the research progress on both cell components and systematic issues is introduced. Benefiting from its fairly mature technology stage, the PEM-based URFC has already been applied in aerospace and terrestrial areas. However, for large-scale application, their cost and efficiency are still the obstacles when competing with other energy storage technologies. As for the alkaline, solid oxide and microfluidic types of URFC, their research progress is reported independently in part B of this review.

Fuel cells and solar energy are promising candidates for electricity generation. It is forecast that fuel cells and solar power systems will play an important role in reducing the greenhouse gas footprint and replacing fossil fuels. Therefore, the limitations of fuel cells and solar power systems, such as low efficiency, high cost, and low reliability, must be addressed appropriately to enable their full potentials. Metal foam is a new class of material that has gained immense attention due to its excellent properties suitable for a wide range of applications. Its unique characteristics distinguish it from typical solid metals. The properties of metal foam can be modified during the fabrication stage by manipulating its physical structure. The goal of this paper is to review the application of metal foam in fuel cells and solar power systems. Besides, the performance of metal foam in fuel cells and solar systems is also discussed. Metal foam has been applied to the electrodes, gas diffusion layer and flow field of fuel cells to enhance performance, especially in regard to current density and flow distribution. Furthermore, metal foam is a heat exchanger for the solar energy harvesting system to improve its efficiency. Superior performances in experimental testing allows the possibility of commercialization of metal foam products in the renewable energy field.

Non-precious-metal single atom (NPM-SA) confined nanomaterials with maximum metal atom utilization have recently attracted particular interest, providing opportunities for exploiting novel heterogeneous electrocatalysts with low cost and high efficiency. The applications of non-precious-metal single-atom catalysts (NPM-SACs) have been extensively developed in electrochemical energy technologies such as fuel cells, metal-air batteries, and hydrogen production via water splitting. NPM-SACs can be confined on substrates with various structures and dimensions from 1D to 3D. However, the role of the structural dimensions of substrates has not been critically summarized. In this review, recent advances in NPM-SACs such as facile synthesis, characterization, performance in catalyzing oxygen redox reactions, and related applications are highlighted through a focus on different dimensional substrates (1D, 2D, and 3D). The general fabrication strategies and the catalytic mechanism of NPM-SACs in the oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) are extensively discussed. Moreover, the opportunities and challenges in this emerging field are presented on the basis of its current development.

International water security has become unprecedentedly complicated, therefore, effective and selective removal of hazardous materials, especially toxic heavy metal ions, are significant for effluent purification. In this regard, ion-imprinted polymers with special recognition cavities have received much attention. However, configuration screening and performance optimization of functional materials by trial-and-error design method is undoubtedly time- and money-consuming. In this study, high-performance ion-imprinted chitosan microspheres (ICSMs) were successfully designed via density functional theory (DFT) calculation and synthesized via facile microfluidic technology. As-synthesized ICSMs exhibited highly uniform morphology (Dav = 420.6 µm, CV = 3.6%) and ultra-high adsorption capacity (qmax = 107.12 mg g−1). The adsorption isotherm was best fitted to the Langmuir model while the kinetic data followed the pseudo-second order model, indicating a dominant role of chemisorptions. Also, ICSMs displayed satisfactory stability and reusability (95.34 mg g−1, after 5 cycles). Moreover, the selective adsorption mechanism was quantitative revealed by electronegativity, electrophilicity index, adsorption energy (Ea) and bond length. This study is expected to lay a foundation for high-performance biosorbents design and synthesis for future water remediation. [Display omitted] •High-performance ICSMs were obtained by DFT-guided design and microfluidic synthesis.•Ultra-high adsorption property for targeted metal ions (107.12 mg g−1) was proved.•Target ions selective removal from mono- and multi-component systems was achieved.•Selectivity mechanism was quantitative revealed by adsorption energy and bond length.•Superior and stable re-adsorption efficiency (> 95 mg g−1 after 5 cycles) was verified.

•A formic acid microfluidic fuel cell based on counter-flow design is proposed.•Highest fuel utilization of 91.4% is obtained at 1μLmin−1.•Pump energy consumption is reduced to minimal.•Ohmic resistance in electrolyte is the major performance limiting factor. Microfluidic fuel cell (MFC) is a promising energy source for portable applications, which draws lots of R&D attention. However, MFCs fed with hydrocarbon fuel like formic acid suffers low fuel utilization problem because of sluggish kinetics, complicate reaction condition and dilemma on cell control. In this work, a formic acid MFC based on counter-flow design is proposed. This counter-flow structure is verified a promising design for high Graetz number operation, which is especially beneficial for high fuel utilization manipulation of MFC. A breakthrough in fuel utilization is achieved and the highest fuel utilization of 91.4% is obtained at 1μLmin−1. It is revealed that counter-flow MFC is capable for low flow rate operation, which is significant for reduce the pump energy consumption and improve the energy efficiency of MFC system. Each potential loss involved in counter-flow MFC is categorized and it is found that potential loss caused by internal resistance hinders performance mostly.

► Limiting factors of air-breathing laminar-flow based fuel cell (LFFC) is analyzed. ► A numerical model for LFFC is developed. ► Air breathing process is not a limiting factor at the present stage. ► Oxygen starvation is significant when the cell current density exceeds 200mAcm−2. Laminar flow-based fuel cell (LFFC) is a relatively new type of fuel cell that does not require the use of proton exchange membrane. While the first-generation LFFC uses dissolved oxygen at the cathode, the second-generation LFFC (2G-LFFC) adopts a more advanced air-breathing design for achieving high power density. The architecture and operational mechanisms of a 2G-LFFC are more complex. In order to gain detailed understanding of the 2G-LFFC, an integrated CFD/electrochemical kinetics modeling study has been conducted to analyze the cell limiting factors and sufficiency of the oxidant supply from air. It is found that under most typical operating conditions, the 2G-LFFC free-breathing mode can supply sufficient oxygen to the electrode reactive surface for cathode half-cell reaction, indicating that the air breathing process is not a limiting factor to the cell performance. However, oxygen starvation will become a major performance limiting factor when the anode is enhanced for higher current density. The results presented in this paper provide useful design guidance for future development of LFFC.

In this paper, a novel Multi-Stage Exhaust Energy Recycling strategy was proposed and optimized to maximize the system efficiency and performance of solid oxide fuel cell -combined heating and power (SOFC-CHP). Both process modeling and experiment work based on 1 kW SOFC-CHP systems were carried out to prove the concept and optimize the system. It is found that the system with multi -stage exhaust gas combustion (MS-EGC) will reduce the system operating temperature from 1149 degrees C to 830 degrees C, which significantly increases the safety of system operation and reduces the material requirement. The system combining MS-EGC with anode off gas recovery (MS-AOGR & EGC) leads to highest overall co-generation efficiency up to 92%. A coupled reactor integrating MS-EGC modules was developed and tested for a 1 kW SOFC system to realize the proposed strategy. The results showed that in MS-EGC, recycling of thermal energy at first stage rarely affects the chemical energy utilization in subsequent stages and the overall system performance, further confirming the advantages of the innovative multi-stage energy recycling strategy. (C) 2017 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY license

Proton-exchange membrane fuel cells (PEMFCs) are considered one of the viable solutions to the decarbonization of the transport sector. However, their performance and durability are yet to be competitive with internal engine vehicles due to the complex interaction of electrochemical and physical phenomena in PEMFCs. The electrochemical and physical phenomena that occurred in PEMFCs, including the polarization curves, profiles of the reactant and product species, velocities of species, as well as temperature distribution, could be described by coupling the reaction kinetics with the transport processes of mass, momentum, energy, and charge. In this chapter, the fundamentals and operating principles of PEMFCs are explained along with the governing equations that describe various electrochemical and multiphysics transport processes in PEMFCs.

For the next generation of proton exchange membrane (PEM) fuel cells, the conventional electrode with uniform distribution of functional components is urged to be replaced by functional graded electrode for the prominent performance, efficiency and avoid exacerbated catalyst cost. Due to the complex and non-linear behaviours of PEM fuel cell system, rapid and effective computational model and optimisation algorithm are required to handle such a complex relationship between electrode design parameters and cell performance. In this work, a multi-physics model with multi-directionally graded electrode is developed, in which a deep machine learning approach is embedded, to create a surrogate model for multi-objective optimisation empowered by non-dominated sort genetic algorithm (NSGA-II). A robust prediction deep neural network model with the mean square error lower than 0.01 is obtained from training and then coupling with NSGA-II to evaluate and optimise the fuel cell performances and cost. Remarkably, the Pareto front is successfully defining the trade-off relationship between the objectives where it aids to identify an optimum point where it satisfies the cost effectiveness while maintaining relatively high cell performances. Our work presents a promising strategy to optimise the fuel cell system with underlying interaction and allow rapid and accurate prediction and optimisation.

[Display omitted] •Factory-on-chip concept is demonstrated with multi-dimensional scale-up strategy.•Design principle is derived with the flow resistance model of a 3D microfluidic flow network.•A module with 80 channels is fabricated and investigated with two fluid systems.•Chitosan/TiO2 composite material is continuously synthesized and characterized. Droplet microfluidics provide an advanced platform for functional material synthesis. However, the process has been largely limited to the scale of laboratory study with the device known as lab-on-chip. Here, a multi-dimensional scale-up strategy based on modularised microfluidic reactors is presented to develop large-scale devices defined as factory-on-chip, achieving throughput enhancement to the industrial production scale. Under the guidance of the derived principle, an up-scaling system is demonstrated with eight microchannels parallelized to form an array, ten arrays stacked as the module, and five modules integrated in a system with 400 channels in total. Experiments showed that the circular array arrangement improved the uniformity of product droplets by 42.4% compared to that achieved with a parallel array. The stacking effect was also investigated with two types of material production systems. Chitosan/TiO2 composite microspheres, as advanced wastewater treatment material, were continuously synthesized in mass production with a narrow size distribution of 3.59%, which could hardly be achieved with conventional methods. The material exhibited a methyl-orange dye removal efficiency of 65.3%, which constitutes an improvement of 10.8% compared to single-component chitosan microspheres.

Titanium dioxide nanoparticles were obtained by using poly-acrylic acid gel in a two-step synthesis method at room temperature using titanium (IV) chloride as titanium source. The formed nanoparticles were studied by different characterization techniques, showing that different proportion of anatase/rutile phase can be obtained by adjusting the amount of acrylic acid in the initial gel. Aluminum storage performance of the synthesized materials was also investigated, obtaining higher capacity density results at higher rutile ratio (75.1 mAh g–1).

A dimensionless steady-state computational model was developed for microfluidic fuel cell (MFC) with flow-through porous electrodes. The dimensionless nature of the model featured with high versatility as a single set of modeling analysis could interpret a wide range of MFCs in terms of fuel cell properties, physical dimensions and scales. Based on the model, statistical Multi-Parametric Sensitivity Analysis (MPSA) was implemented to evaluate the effects of different parameters on the cell output. Eleven major parameters, grouped in terms of cell operation, charge transport, mass transport and porous structure, were investigated under different working conditions. These parameters were consequently classified into strong-, moderate- and weak-influencing factors. The results showed that the charge transfer coefficient and the equilibrium potential were the most influencing factors. The results indicated that the relationship between charge transfer coefficient and porous electrode properties needed to be further specified and the commonly used uniform equilibrium potential assumption of the porous electrode was questionable. Based on the results, guidance for the future modeling and experimental research on MFC was provided. (C) 2015 Elsevier Ltd. All rights reserved.

Sustainable chemistry for renewable energy generation and green synthesis is a timely research topic with the vision to provide present needs without compromising future generations. In the era of Industry 4.0, sustainable chemistry and process are undergoing a drastic transformation from continuous flow system toward the next level of operations, such as cooperating and coordinating machine, self-decision-making system, autonomous and automatic problem solver by integrating artificial intelligence, data and hardware in the cyber-physical systems. Due to the lack of convergence between the physical and cyber spaces, the open-loop systems are facing challenges such as data isolation, slow cycle time, and insufficient resources management. Emerging researches have been devoted to accelerating these cycles, reducing the time between multistep processes and real-time characterization via additive manufacturing, in-/on-line monitoring, and artificial intelligence. The final goal is to concurrently propose process recipes, flow synthesis, and molecules characterization in sustainable chemical processes, with each step transmitting and receiving data simultaneously. This process is known as ‘closing the loop’, which will potentially create a future lab with highly integrated systems, and generate a service-orientated platform for end-to-end synchronization and self-evolving, inverse molecular design, and automatic science discovery. This perspective provides a methodical approach for understanding cyber and physical systems individually, enabled by artificial intelligence and additive manufacturing, respectively, in combination with in-/on-line monitoring. Moreover, the future perspective and key challenges for the development of the closed-loop system in sustainable chemistry and process are discussed.

•Sophisticated physics-based reactor-scale models for EW-based CO2 capture were developed.•Two data-driven surrogate models, RSM and E-AHF, were developed.•Relationship between five design variables and three objective functions were investigated.•E-AHF surrogate model shows higher accuracy than the RSM approach.•Reactor performance was significantly improved after GA-based multi-variable optimisation. Enhanced weathering (EW) of minerals could potentially absorb atmospheric CO2 at gigaton scale per year and store it as bicarbonate and carbonate in the ocean. However, this process must be accelerated by engineered reactors, in which optimal reaction conditions maximise the CO2 capture rate and minimise the energy and water consumption. In this work, trickle beds (TBs) and packed bubble columns (PBCs), operated with fresh water and CO2 -rich flue gas, are chosen as typical chemical reactors to perform the EW-based CO2 capture. We firstly develop experimentally validated physics-based mechanistic models then generate data to train data-driven surrogate models to achieve rapid prediction of performance and multi-variable optimization. Two surrogate models, namely, response surface methodology (RSM) and extended adaptive hybrid functions (E-AHF), are developed and compared, in which the effect of five design variables on three objective functions are investigated. Results show that the R2 for the prediction of CO2 capture rate (CR) and water consumption (WC) through RSM and E-AHF is higher than 0.84. For TB reactors, in particular, the calculated R2 is higher than 0.96. The prediction accuracy of energy consumption (EC) through the RSM approach is, however, relatively poor (R2 ∼ 0.79), but is improved by using the E-AHF surrogate model, increasing to R2 ∼ 0.89. The developed data-driven surrogate model can rapidly predict the performance indicators of TB and PBC reactors without solving complex mechanistic models consisting of many partial differential equations. After optimization using the surrogate models, improvements were achieved in the objectives for TB and PBC reactors as follows: CR increased by 37.8 % and 13.1 %, EC reduced by 37.4 % and 23.8 %, and WC reduced by 12.5 % and 40.7 %, respectively.

Next-generation ultrahigh power density proton exchange membrane fuel cells rely not only on high-performance membrane electrode assembly (MEA) but also on an optimal cell structure. To this end, this work comprehensively investigates the cell performance under various structures, and it is revealed that there is unexploited performance improvement in structure design because its positive effect enhancing gas supply is often inhibited by worse proton/electron conduction. Utilizing fine channel/rib or the porous flow field is feasible to eliminate the gas diffusion layer (GDL) and hence increase the power density significantly due to the decrease of cell thickness and gas/electron transfer resistances. The cell structure combining fine channel/rib, GDL elimination and double-cell structure is believed to increase the power density from 4.4 to 6.52 kW L-1 with the existing MEA, showing nearly equal importance with the new MEA development in achieving the target of 9.0 kW L-1.

The dead-ended anode (DEA) and anode recirculation operations are commonly used to improve the hydrogen utilization of automotive proton exchange membrane (PEM) fuel cells. The cell performance will decline over time due to the nitrogen crossover and liquid water accumulation in the anode. Highly efficient prediction of the short-term degradation behaviors of the PEM fuel cell has great significance. In this paper, we propose a data-driven degradation prediction method based on multivariate polynomial regression (MPR) and artificial neural network (ANN). This method first predicts the initial value of cell performance, and then the cell performance variations over time are predicted to describe the degradation behaviors of the PEM fuel cell. Two cases of degradation data, the PEM fuel cell in the DEA and anode recirculation modes, are employed to train the model and demonstrate the validation of the proposed method. The results show that the mean relative errors predicted by the proposed method are much smaller than those by only using the ANN or MPR. The predictive performance of the two-hidden-layer ANN is significantly better than that of the one-hidden-layer ANN. The performance curves predicted by using the sigmoid activation function are smoother and more realistic than that by using rectified linear unit (ReLU) activation function.

Carbon is one of the most attractive electrode materials for electrochemical energy storage. An ideal electrode structure requires a pore distribution ranging from nanoscale to milliscale to simultaneously enable efficient mass transfer, enlarge the specific surface area, and minimize the electrical resistance. Here, a novel hybrid method to fabricate carbon electrodes with a designable hierarchical pore structure is presented. The proposed manufacturing combines stereolithography, pyrolysis, and chemical activation, which contribute to producing pores in millimeter, micrometer, and nanometer, respectively. The prepared hierarchical microarchitectural material outperforms the commercial carbon paper by five times in current density. Further enhancement in the electrochemical performance can be achieved through optimizing the distribution of hierarchical pores, which is proved feasible in the applications of vanadium redox flow battery and supercapacitor applications.

Microfluidic fuel cell (MFC) is a considered as a promising energy source for powering portable electronic devices due to low cost and easy control. However, the energy density of MFC is much lower than conventional batteries like lithium battery. Due to the fuel crossover, the optimized operation concentration remains 1-2M. In this paper, a counter-flow MFC is presented to achieve concentrated fuel. Density mismatch between fuel and electrolyte is the key cause for fuel crossover. Experimental and modeling study confirms that through adjusting different channel design according to fuel concentration, fuel crossover can be prevented.

The pH-differential membraneless architecture could enhance the thermodynamic property and raise the electrochemical performance of a dual electrolyte microfluidic reactor (DEMR) for electrochemical conversion of CO2. Freed from hindrances of membrane structure and thermodynamic limitation, DEMR demonstrates the possibility of altering anolyte and catholyte pHs to achieve higher reactivity rates and efficiencies. Different operation condition parameters of a microfluidic network would affect the reactor performance to a certain extents, constraining further improvement. Therefore, we conducted experimental analysis to study the mechanisms and intrinsic correlations of catalyst to Nafion ratio, microchannel thickness, electrolyte flow rate and CO2 supply for an optimized outcome. A comprehensive investigation on the cell durability was also carried out in the way of repetitiveness and long period operation, regarding both reactivity and efficiency. It was found that the catalyst to Nafion ratio affects the performance in a parabolic relation and there exists optimal values of electrolyte flow rate and microfluidic channel thickness for maximized cell performance. The influence of the reactant CO2 supply rate is not significant above a certain level where kinetics limitation is not dominant. The parametric study provides an operational point of view on the dual electrolyte microfluidic reactor and serves as a tool for DEMR optimization design. (C) 2016 Elsevier Ltd. All rights reserved.

High-performance monodispersed chitosan microparticles for methyl orange (MO) adsorption were synthesized on a microfluidic platform coupled with a cross-linking approach. Batch adsorption experiments were carried out to evaluate the capacity and kinetics of the as-prepared microparticles on the adsorption of MO. Due to the advantage of microfluidics that all the manipulations and operations are related to independent droplets, the prepared microparticles are controlled to within a narrow size distribution (CV = 1.86%) while exhibiting uniform high performance (adsorption capacity = 182 mg g(-1)). Adsorption experiments were carried out under various design and operation conditions. It is found that the adsorption isotherm was well described by the Langmuir model and the adsorption kinetics followed a pseudo-second-order kinetic model. The high performance together with biodegradable feature and low-cost raw material give the microfluidic-synthesized chitosan microparticles a promising potential for future dye effluent treatment.

A comprehensive multiphysics 3D model of an anode-supported planar reversible solid oxide cell (rSOC) with a half-channel-unit-cell geometry is created and validated. The physical phenomena that are modeled include reversible electrochemistry/charge transport, coupled with momentum/mass/heat transport. Several electrode microstructures comprising the homogeneous and functionally graded porosity distributions are applied to the validated model, to evaluate and compare the current-voltage (j-V) performance in both fuel cell mode and electrolysis mode. The results indicate that increasing the porosity in a homogeneous porous electrode does not always promote the cell's j-V performance. An optimal porosity emerges where the effect of porosity on the mass transport is maximized, which ranges between 0.5 and 0.7 in the working conditions of the present study. Compared with homogeneous porous electrodes, the heterogeneous porous electrode design with a functionally graded porosity distribution is found to be a potential option to better the overall j-V performance of the rSOC. Furthermore, it is discovered that theoretically grading the porosity in the width direction (i.e., increasing porosity from the center of each gas channel to the center of each adjacent rib) brings an outsize benefit on the cell's performance, compared to the traditional way of improving the porosity along the cell thickness direction.

Photocatalytic oxidation has been widely investigated and applied to perform degradation of organic pollutants in water and air. In recent technological advancement, photocatalysis (PC) is integrated into fuel cell (FC) to form photocatalytic fuel cell (PFC) for simultaneous wastewater treatment and production of electricity. In the PFC mechanisms, the organic pollutant, acting as a fuel in the fuel cell component, is decomposed upon light activation at the photoanode and the flow of photoexcited electrons is driven by the potential difference between the two electrodes. Thus, unwanted electron-hole recombination is effectively inhibited, resulting in enhanced PC activity. In other words, the chemical energy stored in the organic pollutant is recovered and converted into useful electricity during the wastewater treatment process. The photoelectrochemical technology can also be implemented for hydrogen generation and carbon dioxide reduction. Various strategies have been investigated for improving the PFC mechanisms through better visible-light photoelectrodes, innovative cell designs, dualphotoelectrode setup, as well as optimal control. In this review, the fundamentals and technological development of PFC will be discussed with special attention to novel cell configurations. With better knowledge and understanding of the PFC, we can identify promising research directions to further develop the PFC technologies.

Aluminum-air cell, with trivalence redox couples, attracts a lot of interest to break the capacity limitation of conventional batteries in pursuit of higher mobility for portable devices. In order to overcome the self-discharge issue of aluminum, a microfluidic aluminum-air cell working with methanol-based anolyte was developed in this work. The operation feasibility of this membraneless cell was first proved. Then, the influences of electrolyte concentration and water content in the methanol-based anolyte on cell performances were investigated. Experimentally, a high discharge capacity density of 2507 mAh/g was achieved at a low current of 0.015mA.

Air-cathode microfluidic fuel cells are promising micro-scale power sources that unfortunately undergo substantial performance loss at the cathode. This study therefore develops a mathematical model to gain a better understanding of the fundamental processes and polarization characteristics associated with the MFC air cathode operation so as to find strategies to minimize the cathode polarization. The model is solved for the four regions of an MFC cathode compartment (i.e. gas channel, gas diffusion layer, catalyst layer and electrolyte microchannel), and considers microfluidic flow, species transport, charge transport and multi-step oxygen reduction reactions. Relying on the model, transport and chemical patterns inside the MFC cathode compartment are examined. Corresponding electrode polarization behaviors are analyzed over a wide operating potential range including different forms of resistance. Through a series of model-based parametric studies, it is found that the internal transfer resistance slightly decreases with increasing catalyst layer porosity but can be effectively reduced through a proper control of electrolyte hydrodynamic conditions, indicating microfluidic technology is a powerful tool for enhancing electrochemical cells. Copyright (C) 2011, Hydrogen Energy Publications, LLC. Published by Elsevier Ltd. All rights reserved.

[Display omitted] •Amphoteric carboxymethyl chitosan/gelatin microspheres (CCGMs) with hierarchical porous structure were synthesized.•Ultra-high adsorption properties (383.142 mg g−1 for MO and 584.795 mg g−1 for MB) were demonstrated.•pH induced selective removal of cationic and anionic dyes from the binary mixed solution was achieved.•Selectivity mechanism was illustrated as the synergy of electrostatic interaction and π-π stacking.•Superior and stable re-adsorption efficiency, higher than 80% after 5 cycles, was realized. The substandard discharge of highly toxic dyestuff wastewater will pose a serious threat to the environment and human beings, even causing unimaginable irreversible damages. In the current study, novel amphoteric carboxymethyl chitosan/gelatin microspheres (CCGMs), synthesized by a facile inverse suspension route with two-step successive crosslinking process, were evaluated as a potential adsorbent for high efficient pH induced selective removal of azo-dyes. The as-prepared CCGMs were characterized using scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FT-IR), thermogravimetry analysis (TGA) and X-ray photoelectron spectroscopy (XPS). Various influential factors such as solution pH, temperature, and contact time were employed to ascertain the optimal condition for representative azo-dyes adsorption, including methyl orange (MO) and methylene blue (MB). The maximal adsorption of MO and MB on the CCGMs at pH values of 3 and 11 were 383.142 mg g−1 and 584.795 mg g−1, respectively. The adsorption mechanism were demonstrated as the synergistic effect of electrostatic interaction and π-π stacking between dyes and CCGMs. Besides, the outstanding and stable regeneration of as-prepared CCGMs were also verified with five consecutive recycling. Thus, the newly developed CCGMs could be a highly promising candidate for dyestuff wastewater treatment.

We investigate different operating conditions effects, including cathode relative humidity, anode stoichiometry and inlet pressure, on PEMFC with anode recirculation by conducting dynamic simulations. The performance improvement caused by the self-humidification effect is about 6.5% with dry cathode inlet, and it is very slight with fully humidified cathode inlet. Nitrogen fraction in the anode is low in the first 20 min under a low cathode relative humidity. A 0.3–0.6 cathode relative humidity might be suitable for the simulated cases. Generally, the fuel cell benefits from increasing anode stoichiometry by enhancing the self-humidification effect, decreasing the performance decline rate and ameliorating hydrogen distribution along the channel. Increasing anode inlet pressure and cathode inlet pressure play the mitigated and exacerbated role on voltage decline, respectively. However, increasing cathode inlet pressure can significantly improve output performance especially under a low cathode relative humidity. We suggest an appropriate low cathode relative humidity, increasing anode stoichiometry, and increasing anode and cathode inlet pressure by similar amount for PEMFC with anode recirculation. •Modeling of operating condition effect on anode recirculation PEMFC is presented.•An appropriate low cathode humidity is proposed for low nitrogen crossover rate.•High anode stoichiometry can improve fuel distribution and mitigate voltage decline.•Increasing anode and cathode inlet pressure by similar amount is recommended.

Microfluidic fuel cells and flow batteries are free from the static physical barrier that separated the anodic and cathodic compartments, introducing the advantages of low cost and feasible miniaturized application. Recently, the concept of dual electrolyte stream proves itself an effective strategy to enhance the reactor performance by pairing catholyte and anolyte with thermodynamically favored pHs. Being able to be implemented in both fuel cell and electrolyzer modes, the dual electrolyte strategy demonstrates superior peak power density, low overpotentials, high reactivity, and high efficiency. However, keeping the characteristics of laminar flow requires continuous electrolyte flowing in the microchannel. Besides, neutralization reaction would occur within the mixing layer between the catholyte and the anolyte, requiring higher flow rate to control the layer thickness. These lead to considerable electrolyte wastage that will significantly weaken the economical aspect and electrolyte utilization efficiency. To tackle this issue, this study investigated the electrolyte degradation process and proposed an operation scheme for electrolyte recycling. Key parameters of electrolytes were tracked and monitored by mimicking different reactor situations. Results indicated that with appropriately adjusted operating conditions, electrolyte recycling would be feasible in a microfluidic pH-differential network. Accordingly, an pH indicator for electrolyte recycling was proposed for potential practical application. •Electrolyte recycling feasible on dual electrolyte microfluidic networks.•Key operation conditions optimized for better recycling operation.•pH degradation predictable for practical applications.•Reactor performance can be controlled within a stable range.

Microfluidics has been proved a promising way for highly efficient lanthanide extraction and separation benefiting from the astounding mass transfer characteristics. Efforts have been devoted by us previously to provide a clear understanding of the separation intensification mechanism of lanthanide pairs with distinguished extraction kinetics in microfluidics, such as Eu 3+ /La 3+ . However, for those lanthanide pairs with closely similar extraction kinetics, the working principles of separation intensification are different, which could not be explained by our former proposed theory of nonequilibrium separation intensification. In this study, a numerical model considering nonlinear extraction kinetics was presented to comprehend the separation characteristics of Eu 3+ /Sm 3+ , a lanthanide pair with very similar extraction kinetics, in microfluidics. The hydrodynamic and kinetic approaches, i.e. flow rate, initial concentration of metal ions and extractant, pH and temperature, were studied to manipulate separation performance. Analyses on dimensionless number (Damköhler number) were conducted to unveil the working mechanism of such approaches. The numerical study provides a mechanistic understanding of lanthanide separation in microfluidics and offers manipulating principles for further optimization.

Solid oxide electrolysis cell (SOEC) is a novel approach to utilize excess renewable power to produce fuels and chemicals. However, the intermittence and fluctuation of renewable energy requires more advanced optimization strategy to make sure its performance in safety and cost-effectiveness. Here, we propose a hybrid model for the precise and quick optimization of the co-electrolysis process in the SOEC for syngas production, based on the multi-physics simulation (MPS) and deep learning algorithm. The hybrid model fully considers electrochemical/chemical reactions, mass/momentum transport and heat transfer, and presents a small relative error (96%). Various targets including the single-objective, dual-objective and multi-objective optimizations are evaluated with particular attentions on the reactant conversion rate and energy efficiency at different temperatures. The electrolysis efficiency is negatively correlated with the power supply in all strategies and thermal neutral condition (TNC) can be achieved at different temperatures, where 1023 K, 1053 K, 1083 K and 1113 K are corresponded to the TNC power range of 10-16 W, 14-23 W, 18-29 W and 22-37 W, respectively. This theory can be flexibly applied in the sustainable manufacturing and circular economy sectors and energy according to the optimization targets.