Research

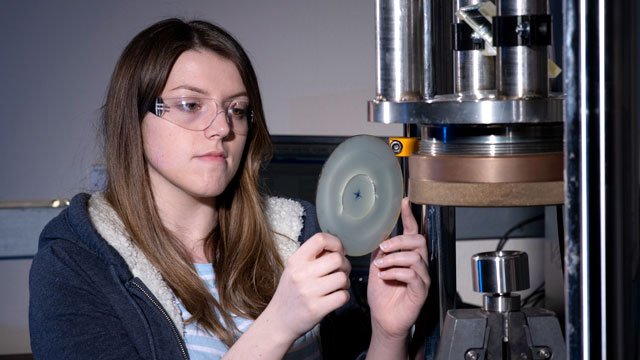

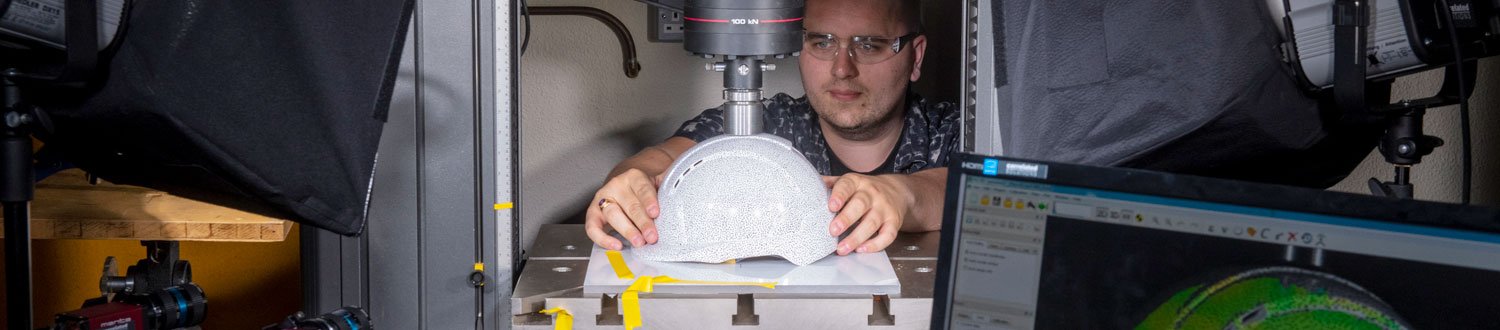

Our research examines all classes of materials with applications across all sectors aimed at bringing about improved performance and capability. Our work is conducted through three interconnected research challenge areas.

Research activity

Our research seeks to provide viable solutions for real-world problems.

Mechanical engineering research centres and groups

Take a look at the other research we do within the School of Mechanical Engineering Sciences.