Sonochemistry Ultrasonics Research Group

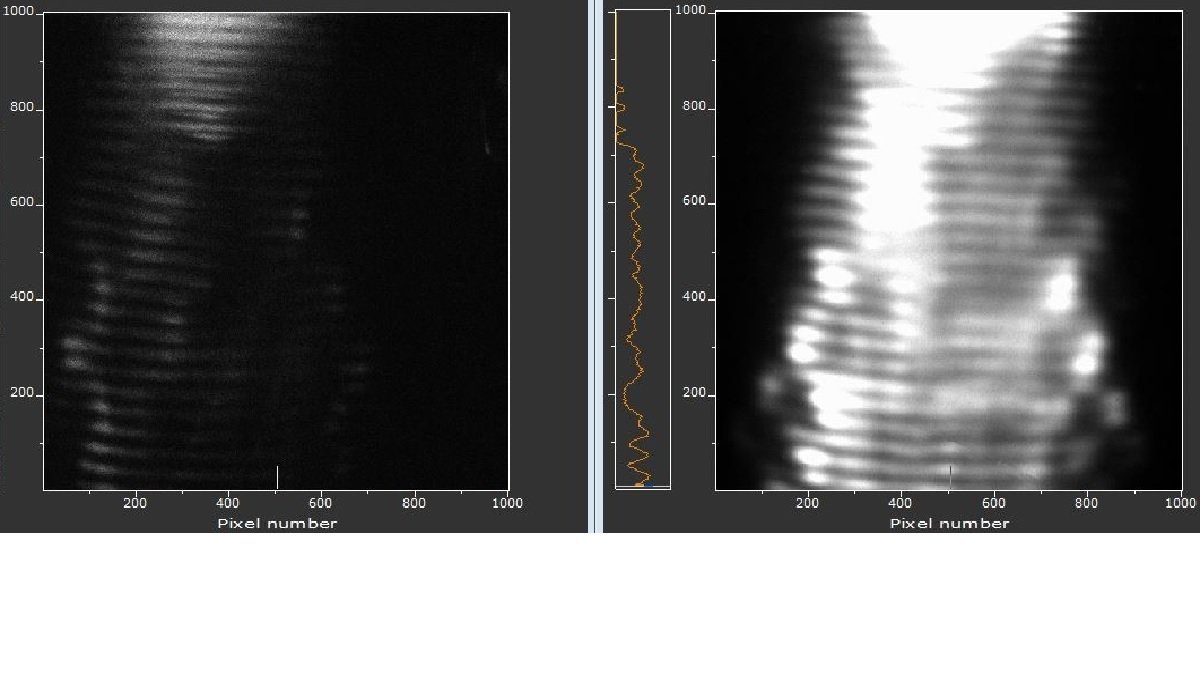

We work with the propagation of ultrasound waves through a liquid medium that can lead to the creation of acoustic cavitation bubbles. These cavitation bubbles can emit light (sonoluminescence) and undergo violent collapse to generate extreme temperatures (> 5000 k), pressures (> 1000 atm) and jet velocities (up to 120 m/s has been reported).

Overview

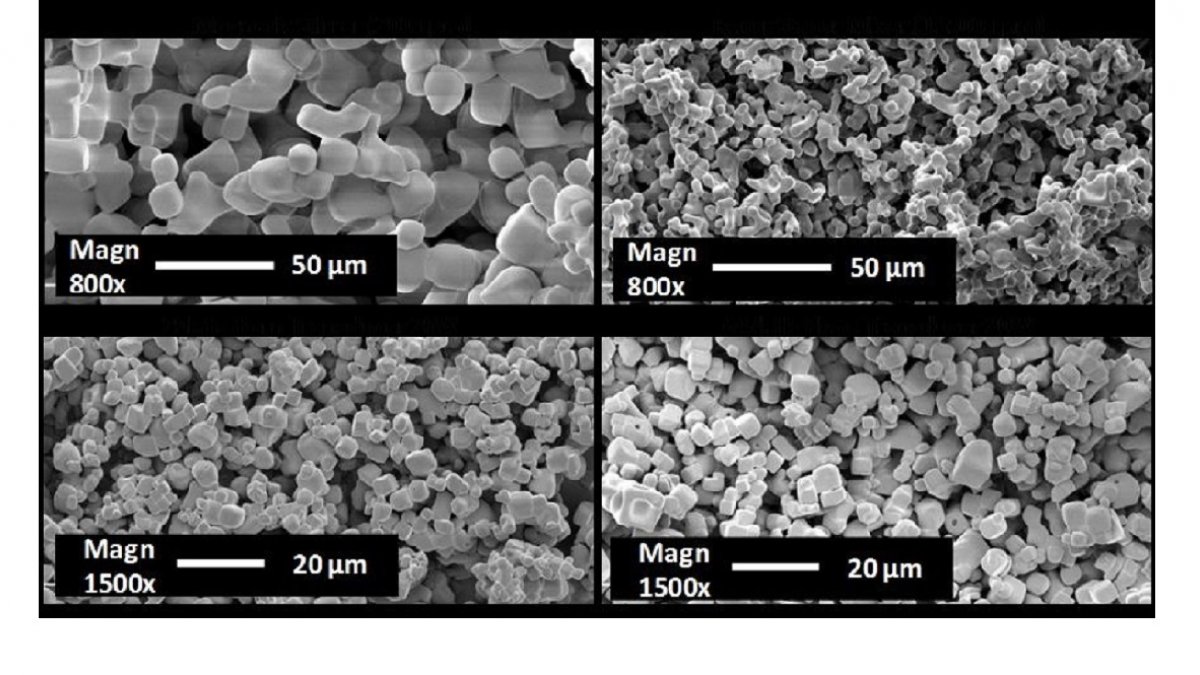

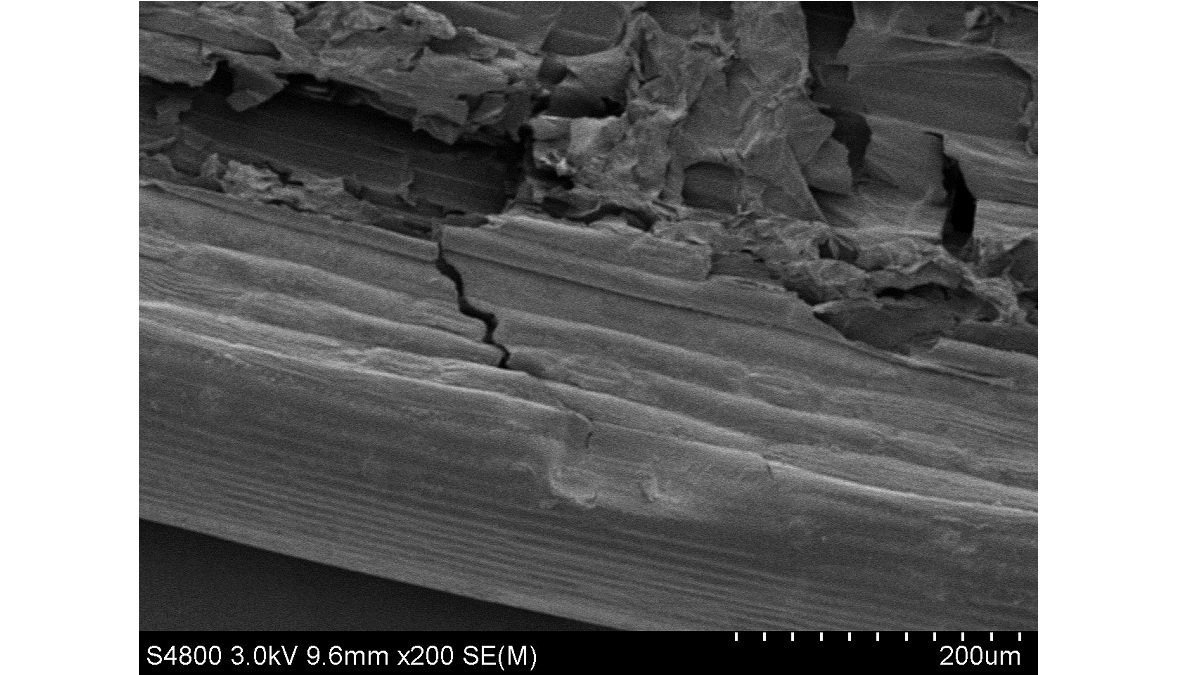

It is these remarkable conditions that allow ultrasound to create unusual physical and chemical properties ideal for degradation of pollutants, synthesis of polymers and nanomaterials. However, to capitalise on these effects, one needs to understand how the physical and chemical properties vary under different solution and sonication conditions such as frequency and power.

Ultrasonic processing has applications in heterogeneous and homogeneous environments, and is able to augment chemical processes via the well-known mechano acoustic and sonochemical effects from the cavitation bubbles. This can enhance radically driven processes, as well as mixing, emulsification and molecular accessibility.

The mechanism and level of enhancement is influenced by the reactor configuration (geometry, transducer type, frequency, flow, power) and the characteristics of the medium (gases present, solid loading, form of the solute, pH etc). Therefore it is of interest to investigate the effect of these parametric variations to further capitalise on the bubble dynamics to enhance the desired ultrasonic effects.

Available equipment

The equipment we have available is able to investigate the various parametric effects of ultrasound on a multitude of processes, aimed at understanding the fundamental interactions toward process improvement and optimisation.

Industrial collaborators

Examples

Facilities

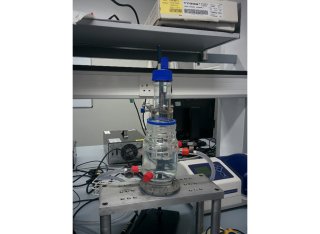

Multi-frequency reactor and amplifier sets consisting of an amplifier, transducer, impedance matching and different reactor options for specialised work.

The cavitation within an ultrasonic cleaning bath can be demonstrated with a simple aluminium foil test and provides a good comparison of ultrasonic applications, repeatability and effects at low frequencies and powers.

Ultrasonic horn is a high power, low frequency means of introducing ultrasound into solution. The tip of the horn is interchangeable with a micro-tip and is used for emulsification applications, cell deactivation.

Our people

Select the profiles below to view their publications.

Lead researchers

Dr Madeleine Bussemaker

Associate Professor in Chemical Engineering

Professor Judy Lee

Professor in Chemical and Process Engineering

Contributing academics

Dr Devendra Saroj

Reader & Head of Centre for Environmental Health & Engineering (CEHE), Fellow of Institute for Sustainability, University of Surrey; Adjunct Professor, Indian Institute of Technology (IIT) Delhi India; Visiting Professor, DL Salle University, Philippines

Dr Richard Sear

Associate Professor (aka Reader), Soft Matter, Biological and Medical Physics Group leader, Sustainability Fellow with the Institute for Sustainability

Dr Patrick Sears

Senior Lecturer in Chemistry and Forensic Analysis

Postgraduate research students

Dr Tim Sidnell

Ultrasonic degradation of per- and polyfluoroalkyl substances

Irem Soyler

Investigating the efficacy of combined treatments of ultrasound and antimicrobial extract for the inactivation on food pathogens on ready-to-eat salad leaves

Dr Mehrdad Zare

Ultrasonic remediation of pharmaceutical emerging contaminants (ECs) in water/wastewater