Information and process systems engineering

Digital technologies and computation are changing the way that industries and governments make decisions and understand large, complex systems. Developing combinations of first principles and data-driven multi-scale models, we use cutting-edge approaches to understand and manage complex processes and systems to address grand challenges in energy, water, environment, health and food.

Tools and applications

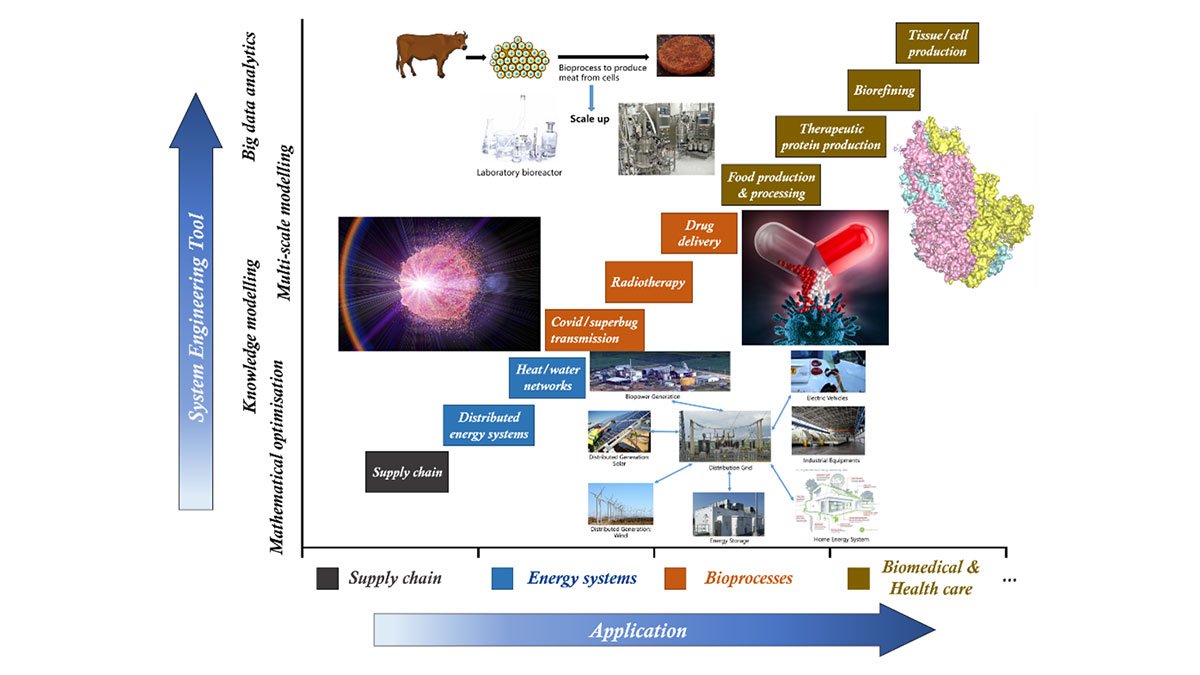

Our group is working on the interplay between novel systems engineering methodologies and important applications, as illustrated in this diagram.

A diagram showing the range of applications and multi-scale tools we use. It shows applications of mathematical optimisation, multi-scale modelling, big data analytics, and knowledge modelling on applications including supply chains, energy systems, food and health applications, biorefining.

Available equipment and software

- High-performance computing resources

- GAMS

- COMSOL multiphysics

- COSMOTherm

- gPROMS process builder.

Collaborations

Combining over 15 years of research expertise and £5million of research funding, we work with industrial and academic partners from around the world to deliver cutting edge solutions to important problems found across diverse industries such as chemicals, pharmaceuticals, energy, consumer goods, agriculture, and biomedical industries.

Industry partners

- BASF

- Chelsea Technologies

- Cosmetics Europe

- CropLife Europe

- Eli Lilly and Company

- Honeywell

- JFE Steel Corporation (Japan)

- Laizhou Mingbo Aquatic Co. Ltd. (China)

- National Metrology Laboratory

- National Physical Laboratory

- Perceptive Engineering

- Process Systems Enterprise

- Royal Surrey County Hospital

- Syngenta

- Unilever

- US Food & Drug Administration.

Small and medium-sized enterprises

- Aria Sustainability Ltd

- Bio-Sep Ltd

- Biox Ltd

- DIREK Ltd

- Hatfields London Ltd

- Inspro Ltd

- Octeract

- Phytoceutical Ltd

- Pplus Skin Care Ltd.

Projects

Completed projects

A software framework for optimal decarbonisation planning for ASEAN countries

Principal investigator: Dr Michael Short

Start date:

End date:

Improving the productivity of topical drug delivery through in situ academic entrepreneurship

Principal investigator: Tao Chen

Start date: February 2021

End date: July 2022

Developing an in-silico - spectroscopic imaging toolkit for assessing skin penetration

Principal investigator: Dr Tao Chen

Start date: October 2020

End date: September 2023

In-silico analysis of tissue specificity of dermal exposure deposition and absorption kinetics

Principal investigator: Dr Tao Chen

Start date: September 2020

End date: September 2024

Start date: September 2018

End date: September 2023

Start date: October 2016

End date: June 2021

Start date: October 2013

End date: September 2017

Meet the team

Along with our research interests and industrial partnerships, we boast a vibrant community of PhD students and postdoctoral research fellows from around the world. View specific research interests, expertise, publications, and contact details via our profiles.

Theme leads

Dr Franjo Cecelja

Reader

Professor Tao Chen

Associate Vice-President, International and Professor in Chemical Engineering

Contributing academics

Dr Madeleine Bussemaker

Associate Professor in Chemical Engineering

Dr Oleksiy Klymenko

Senior Lecturer in Chemical Process Engineering

Professor Guoping Lian

Professor

Professor Jhuma Sadhukhan

Associate Director of Global Center for Sustainable Bioproducts | Associate Director of C-Loop Advanced Manufacturing Hub | ELMENTAL EngBio Mission Hub CoI | Vice Chancellor Researcher of Y2024 | Professor of Environmental, Energy and Chemical Engineering

Dr Michael Short

Associate Professor of Process Systems Engineering

Dr Dimitrios Tsaoulidis

Senior Lecturer in Chemical Engineering

Dr Lei Xing

Lecturer in Digital Chemical Engineering / Fellow of Institute for Sustainability / Fellow of Institute for People-Centred AI

Postgraduate research students

Ishanki De Mel

Project: Optimisation of distributed energy systems

Benaissa Dekhici

PDRA in Bioenergy Process Optimisation and Control

Panagiotis Demis

Postgraduate Research Student

Olcay Gunay

Project: Distributed model predictive control strategies and their applications in chemical engineering

Sahar Hajizeinalibioki

Postgraduate Research Student

Mustapha Hamdan

Postgraduate Research Student

Gul Hameed

Postgraduate Researcher

Shuya Hou

Project: Risk assessment and emergency response study of multiple pool fires domino accidents

Anamika Kushwah

Project: Studying interactions between the catalytic upgrading of biomethane and fuel cells to obtain optimal flowsheets

Yufan Liu

Project: Chemical safety assessment using omics and machine learning technology

Dr Samadhi Silva Silva

Project: Computational modelling of the effect of product formulations on skin penetration

Robert Steven

Postgraduate Research Student

Arek Wojtasik

PhD Candidate/Tutorial Demonstrator

Dapeng Zhang

PhD student

Ruosi Zhang

Project: Optimization of integrated energy systems in aquaculture

Yu Zhang

Digital twin for topical formulation design

Xueliang Zhu

Project: Breakup dynamics of flashing jet throughout accidental release of superheated liquids