Royal Society Summer Exhibition

Plastic Alchemy Recover, Replace, Recycle

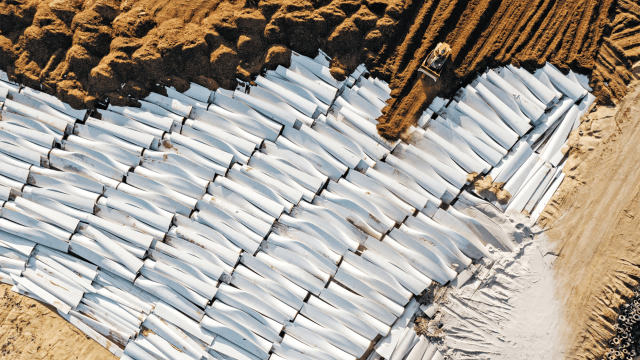

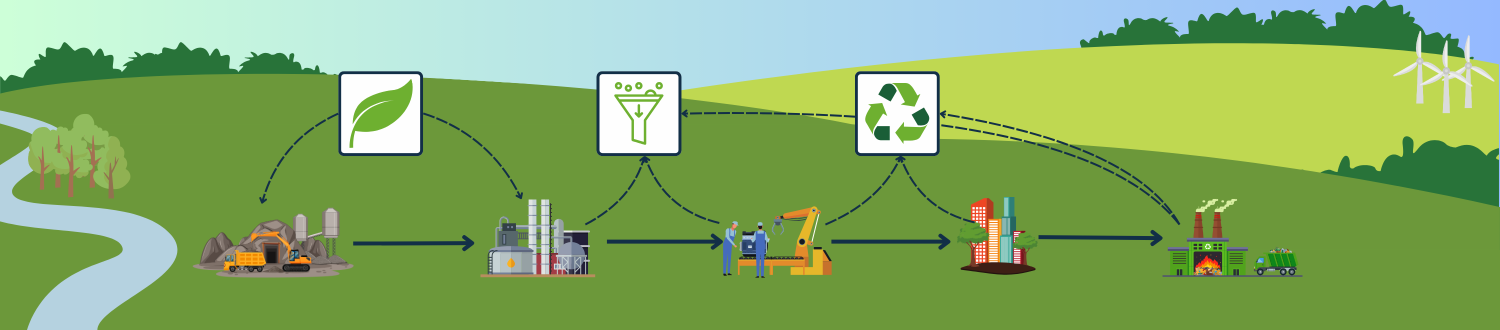

The journey of plastic recycling

See how researchers from the Circular Economy Group at the University of Surrey are working to improve plastic recycling rates and look at innovative methods to recover and recycle plastic waste.

Discover advances through plastic recycling through innovative recovery and processing methods, paving the way for a more sustainable future.

Reduce and replace: research

Professor Joe Keddie at the University of Surrey discusses the options for replacing plastics and his work with Pulpex.

Recover: research

Professor Judy Lee at the University of Surrey discusses the abundance of micro and nanoplastic pollution in waste water and her work on wastewater filtration.

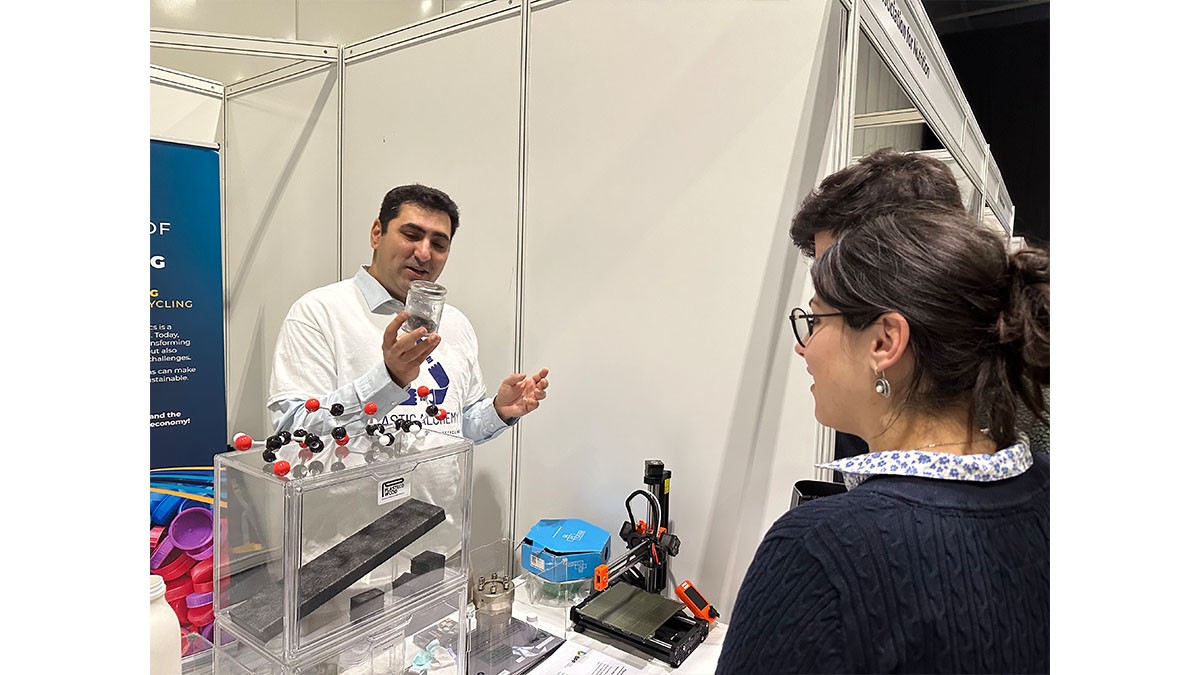

Recycle: research

Dr Iman Mohagheghian at the University of Surrey along with PhD Student James Bowbrick Smith and Dr Henry Yu discuss the unique properties of composite materials, their current end-of-use fate and how they are looking to harness the strengths of recycled materials.

Meet our circular economy researchers

Dr Iman Mohagheghian

Associate Professor (Reader) in Mechanics of Materials

Biography

Dr Iman Mohagheghian is Associate Professor (Reader) in Mechanics of Materials at the University of Surrey. Dr Mohagheghian’s core expertise is around designing, manufacturing, modelling and testing the performance of novel lightweight materials/structures with lightweighting achieved through hybridisation of materials and through introducing multiple functionalities. Dr Mohagheghian is currently leading the Multi-functional, Adaptive and Sustainable Structures (MASS) lab conducting research projects spanning across TRL levels with funding from EPSRC, Innovate UK and industry.

Dr Mohagheghian received his PhD from the University of Cambridge in 2013. He worked in the micro-mechanics lab in the field of impact mechanics. His PhD, was on the application of polymers and polymer nano-composites as lightweight impact energy absorbing materials. Prior to joining Surrey, Dr Mohagheghian was a research associate in the Department of Mechanical Engineering at Imperial College London.

Professor Joseph Keddie

Professor of Soft Matter Physics and Royal Society Industry Fellow

Biography

Joseph (Joe) Keddie is Professor of Soft Matter Physics within the Soft Matter, Biological and Medical Physics Group at the University of Surrey. He is also a Royal Society Industry Fellow and a Fellow of the Institute for Sustainability at Surrey. He leads a vibrant research programme in soft matter physics.

After graduating with a PhD from Cornell University (USA) in 1993, Joe spent two years as a post-doctoral researcher in the Polymer & Colloids Group at the Cavendish Laboratory, University of Cambridge followed by one year as an Oppenheimer Fellow there . At Cambridge, he used spectroscopic ellipsometry and environmental-SEM to study polymer thin films and colloids. In 1995 Joe moved to the University of Surrey as a Foundation Fund lecturer. Throughout his time at Surrey, he has carried out research on soft matter, with special interest in polymer colloids. More recently, research has focussed on sustainable materials and living materials.

In recognition of his contributions to the understanding of polymer dynamics of polymers in thin films and colloidal dispersions, he was awarded the 2001 Paterson Medal and Prize by the Institute of Physics and named a Fellow. His research group has won two Roon Awards from the Federation of Societies for Coatings Technology for papers presented at their Annual Meeting. In 2006 he was inducted into the Phi Beta Kappa honour society by his alma mater, Alfred University. He was selected to deliver the 2017 Thomas Graham Lecture by the RSC/SCI Joint Colloids Group. He held a Royal Society Short Industry Fellowship in 2023 and commenced a four-year Royal Society Industry Fellowship in 2024.

A co-author of >150 journal articles and book chapters, he also holds two US patents and has recently submitted two international patent applications. He has written - along with his co-author, Alex Routh, at the University of Cambridge - a book entitled Fundamentals of Latex Film Formation: Processes and Properties, which was published in 2010 by Springer. His current h-index is 53 (according to Google Scholar).

From 2011 to 2017, he served as the chair of the Polymer Physics Group of the Institute of Physics. He was recently the Awards Co-ordinator for the RSC/SCI Joint Colloids Group.

Professor Judy Lee

Professor in Chemical and Process Engineering

Biography

Academic/research positions

- 2025- : Professor, Chemical and Process Engineering, Surrey University

- 2021-2025: Reader, Chemical and Process Engineering, Surrey University

- 2015-2020: Senior Lecturer, Chemical and Process Engineering, Surrey University

- 2012-2015: DECRA Postdoctoral Fellow (Assistant Lecturer), Chemical and Biomolecular Engineering, Melbourne University, Australia

- 2010-2012: Postdoctoral Fellow, Chemical and Biomolecular Engineering, Melbourne University, Australia

- 2007-2009: JSPS Postdoctoral Fellow, Advanced Industrial Science and Technology (AIST), Japan

- 2006-2007: Postdoctoral Fellow School of Chemistry, Melbourne University, Australia

Areas of specialism

- Acoustic cavitation: Bubble dynamics, Sonoluminescence, Bubble Coalescence, Surfactants etc.

- Ultrasonic processing/synthesis: Crystallisation, Dairy Materials, Wastewater treatment, Emulsions, Nanoparticles, Microspheres etc.

- Membrane filtration: Wastewater treatment and recycling, nano/micro plastic remediation, Dairy whey etc.

Professor Jin Xuan

Associate Dean (Research and Innovation)

Biography

Professor Jin Xuan joined the University of Surrey as the Associate Dean of Research and Innovation for the Faculty of Engineering and Physical Sciences in September 2022. He holds a Chair in Sustainable Processes and a prestigious EPSRC Open Fellowship at the School of Chemistry and Chemical Engineering. He is also a Turing Fellow at The Alan Turing Institute. Before moving to Surrey, he was the Head of the Department of Chemical Engineering at Loughborough University.

Professor Xuan has won a number of prizes and awards in recognition of his research excellence. He is the recipient of the Philip Leverhulme Prize of Engineering in 2022 for his pioneering research on Energy and AI, the Beilby Medal and Prize, jointly from the Society of Chemical Industry (SCI), the Royal Society of Chemistry (RSC), and the Institute of Materials, Minerals and Mining (IOM3) in 2020 for his work that ‘has exceptional practical significance in chemical engineering, applied materials science, energy efficiency or a related field’, and the International Association for Green Energy (IAGE) Technology Innovation Award in 2025 for "pioneering innovative electrochemical techniques exemplifying the principle of circular economy, while promoting environmental sustainability and economic growth". He led the UKRI CircularChem Centre winning the IChemE Global Award for Sustainability in 2023 and the RSC Environment, Sustainability and Energy Horizon Prize: John Jeyes Prize in 2025. He led the Surrey team being part of the Flue2Chem project, named as the UK National Winner of the 2025 Net-Zero Industries Award, announced at COP30.

Professor Jin Xuan is a recognised leader in enterprise and commercialisation, with a strong track record of translating academic innovation into real-world impact. He is the Co-founder and Chief Technology Officer of R3V Tech, developing next-generation circular economy technologies for the chemicals and fuels industries. Under his leadership, R3V Tech has received more than half million GBP funding and been selected for the Shell StartUp Engine and the Royal Society of Chemistry CleanTech Accelerator Cohort. More recently, Professor Xuan also serves as the Principal Academic Advisor to EcoShift.AI, applying artificial intelligence to optimise industrial decarbonisation.

Professor Xuan actively takes leadership in the wider research community. He is an EPSRC Strategic Advisory Team (SAT) member for Energy and Decarbonisation, and a member of the Research, Innovation & Knowledge Transfer Committee of the Engineering Professors’ Council.

Prof Xuan contributed to the establishment of the emerging Energy and AI research community globally. He is the Founding Editor-in-Chief of Digital Chemical Engineering (IChemE), the Founding Editor of Energy and AI (Elsevier), and the co-chair of the International Conference of Energy and AI series (Tianjin 2020, London 2021, Belfort 2022, Xining 2023, Ningbo 2024, Reykjavik 2025). In his Editorial of Energy and AI, he provided a strategic overview in this interdisciplinary research area including wider societal issues such as ethics, morality, policy and law.

Professor Xuan is an advocate for Responsible Assessment. He was interviewed by Nature as part of a news item China bans cash rewards for publishing papers, where he provided his expert view on policy development for proper use of journal metrics in research evaluation. He also actively promotes EDI in the wider research community. He serves as a member of the EPSRC's EDI Strategic Advisory Group and the EDI Champion in the EPSRC Energy SAT. He is the leading author of The equality, diversity and inclusion in energy and AI: Call for actions.

Dr Hui Luo

Royal Academy of Engineering Research Fellow/Lecturer

Biography

Dr Hui Luo is an RAEng research fellow in the School of Mechanical Engineering Sciences, and part of the Surrey Circular Economy Group at the University of Surrey, UK. She is also a Fellow of the Institute for Sustainability, member of the Royal Society of Chemistry (MRSC) and member of the Institute of Materials, Minerals and Mining (MIMMM).

She obtained her PhD in Queen Mary University of London in 2019, working on carbon materials for solar hydrogen conversion. in Oct 2019 she moved to Imperial College London working as a research associate, developing biomass electrolyser for green hydrogen and bio-chemical co-production. In Sep 2022 she worked as a senior test engineering at Ceres, before taking the Surrey Future Fellowship and join Surrey in May 2023.

Her research interests include developing and up-scaling efficient catalytic mechanochemical and electrolysis technologies to convert biomass and plastic wastes into green hydrogen and high-value commodity chemicals. Her expertise includes nanomaterials synthesis and characterisation, water electrolysis and fuel cell technologies, in operando Synchrotron X-ray absorption, surface enhanced Raman and FTIR spectroscopy, as well as gas and liquid chromatography.

Dr Lirong Liu

Associate Professor in Environment and Sustainability

Biography

Dr Lirong Liu is an Associate Professor (Reader) within the Centre for Environment and Sustainability, University of Surrey. She is also appointed as AI Fellow at Surrey Institute for People-Centred Artificial Intelligence.

Her current research focuses on the development and application of systematic models for supporting sustainability, with a focus on climate change mitigation. She has recognized expertise in innovatively integrating methodologies at different scales to address scientific issues with consideration of conflicting environmental, economic and social objectives.

Dr Lei Xing

Lecturer in Digital Chemical Engineering / Fellow of Institute for Sustainability / Fellow of Institute for People-Centred AI

Biography

9Dr. Lei Xing joined the Department of Chemical and Process Engineering, University of Surrey, as a lecturer in September 2022. Prior to this, he worked as postdoctoral research associate in world-leading universities, including Oxford, Purdue and Birmingham, etc. Dr. Lei Xing received his PhD in Chemical and Process Engineering from Newcastle University. His research interests include electrochemical energy conversion (fuel cells, electrolysers), carbon capture and utilisation (CCU), artificial intelligence (AI) and AI-enabled multi-criteria assessment and model predictive control (MPC), with specific focus on multi-physics and multi-phase flow modelling, multi-objective optimisation, techno-economic analysis (TEA) and life cycle assessment (LCA) of renewable energy-based systems.

Dr. Lei Xing has worked across disciplines and established national and international collaborations with colleagues from chemistry, mechanical engineering, electrical engineering, and computer science. He is a Chartered Member of IChemE (MIChemE), fellow of higher education (FHEA), Associate Editor of Carbon Capture Science & Technology, Frontiers in Energy Research, Academic Editor of Fuel Cells, Editorial Board Member of Energy and AI, Energies, etc, and Guest Editor, Topic Editor and Review Editor of several international journals. He has published 4 book chapters, 160+ journal papers, including 6 highly cited papers and 4 journal covers, with h-index of 42, i10-index of 104, and citation over 5700 to date (Feb 2026).

Professor Jhuma Sadhukhan

Associate Director of Global Center for Sustainable Bioproducts | Associate Director of C-Loop Advanced Manufacturing Hub | ELMENTAL EngBio Mission Hub CoI | Vice Chancellor Researcher of Y2024 | Professor of Environmental, Energy and Chemical Engineering

Biography

Professor Jhuma Sadhukhan is an outstanding researcher, co-led strategic large interdisciplinary grants of over £60million. According to science-wide author databases of standardized citation indicators by Stanford University, Professor (Dr) Jhuma Sadhukhan is in the world's top 0.5% of scientists (annual citation) and in the world's top 1% of scientists (career total citation). She served the industry as a Process Systems Engineer (MW Kellogg Ltd., UK, and Technip (KTI Ltd.) India). She has a Master's and a Bachelor's in Chemical Engineering degrees from the Indian Institute of Technology (IIT) Kanpur and Jadavpur University, India. Jhuma obtained a PhD from UMIST (The University of Manchester), UK. Jhuma is a CEng (Chartered Engineer), CSci (Chartered Scientist) and FIChemE (Fellow of the Institution of Chemical Engineers).

She won the University of Surrey Vice-Chancellor’s Awards, two in a row, Public and Community Engagement, 2025, and Researcher of the Year, 2024. Her “research has successfully challenged dogma, created a new field of research, elucidated a new paradigm, made a fundamental change in thinking, or had a significant impact on society.” https://stories.surrey.ac.uk/VC-Awards-2024-winners/index.html#group-section-Researcher-EfRg1VrY6U A world-leading innovator at the nexus of sustainability, engineering, AI and global healthcare, she has successfully challenged traditional approaches and created a new paradigm in lifecycle-inspired resource-efficient climate-resilient circular bioeconomies, integrating molecules to supply chains, adopted across diverse global sectors, from healthcare to manufacturing. She has been a BBSRC Strategic Advisory Panel member (2020-2026), helping to shape the UK’s Engineering Biology Mission for the circular net-zero bioeconomy.

Her Innovate UK Flue2Chem project with fifteen industries is the winner of the UK Net Zero Industry Outstanding Project Award at COP30: https://net-zero-industries-mission.net/national-winners-of-the-2025-net-zero-industries-award-unveiled-at-cop30/. She was the main process integration, life cycle assessment (LCA) and techno-economic analysis (TEA) researcher of Flue2Chem, turning CO2 into high-value surfactants:

1) Sadhukhan, J., Fisher, O.J., Cummings, B. and Xuan, J., 2025. Novel comprehensive life cycle assessment (LCA) of sustainable flue gas carbon capture and utilization (CCU) for surfactant and fuel via Fischer-Tropsch synthesis. Journal of CO2 Utilization, 92, p.103013. https://doi.org/10.1016/j.jcou.2024.103013

2) Fisher, O.J., Sadhukhan, J., Daniel, T. and Xuan, J., 2024. Techno-economic analysis and process simulation of alkoxylated surfactant production in a circular carbon economy framework. Digital Chemical Engineering, p.100199. https://doi.org/10.1016/j.dche.2024.100199

She co-authored a collaborative Nature Chemistry publication on engineering biology:

White M., Trotter C., Lau E., Law S., Gilman J., Steele J., Era Y., Sadhukhan J., Johnson N., Dennis J., Gordon R., Wallace S. 2026. Native H2 Pathways Enable Biocompatible Hydrogenation of Metabolic Alkenes in Bacteria. Nature Chemistry, in press.

New Scientist interviewed and quoted her: Your flight emissions are way higher than carbon calculators suggest | New Scientist, following her other Innovate UK project publication coauthorship in Communications Earth & Environment: https://doi.org/10.1038/s43247-025-02847-4.

Her primary research is at the interface of engineering, sustainability, data and engineering biology. Professor Jhuma Sadhukhan is a global leader in BIOREFINERY DESIGN, PROCESS INTEGRATION AND SUSTAINABILITY ANALYSIS FOR A NET-ZERO CIRCULAR BIOECONOMY. Jhuma is an exceptional scientist and engineer with a leading specialism in biorefining and bio-based product formulations, synthesis and innovations. She wrote the leading only authored biorefinery textbook "Biorefineries and Chemical Processes: Design, Integration and Sustainability", Wiley, 2014. Known as the Green Bible, the book is an internationally leading textbook for teaching and learning biorefineries, excerpted here.

With leading authority, Jhuma edited refereed journal special issues: Sustainable Production and Consumption of Elsevier: sustainable bioresource (biomass) availability, Chemical Engineering Research & Design of Elsevier: biorefinery value chains, Nature Scientific Reports: carbon capture and storage, and Digital Chemical Engineering of Elsevier: industrial digitalisation.

Jhuma develops integrated bioeconomy approaches considering all biological resources including organic wastes, across all sectors, agriculture, forestry, fisheries, and aquaculture, to produce multiple products, food, feed, carbon-based products, goods, and services. Bioeconomy will drive the renewal of our industries, so-called biorefineries, and protect the environment by enhancing biodiversity, and achieve a net-zero sustainable bioeconomy, read also biorefineries and bioeconomy. Biorefinery is an integrated processing system to produce multiple added-value products from waste biomass, excerpted here.

Jhuma for the first time showed extensively, municipal solid waste biorefining into high-value chemical products for mitigating climate change impacts, saving fossil resources and increasing economic margins. Read the news. For this pioneering design, Jhuma's paper received the Best Paper Award on Waste Biorefineries in Bioresource Technology, Elsevier (2016). Her other Best Paper Awards are in Sustainable Chemistry & Engineering (2023) and in Environmental Science-Water Research and Technology (2023). Jhuma also received the IChemE Moulton Medal and the IChemE Hanson Medal for co-authoring the best publications by the IChemE.

Jhuma is the pioneer designer of game-changer non-consumable food waste biorefineries producing surfactants and proteins, excerpted here and comprehensive biorefinery configurations including bioleaching, bioremediation and biorecovery as well as high-value structural polysaccharide and amino acid extractions for food and medicinal applications; she provided a biorefining production guidance, for pharmaceuticals, food ingredients, personal, health, home care and building block chemicals, alongside the most efficient processing steps, e.g., protein separation from polysaccharides and their valorisation into amino acid and structural polysaccharide extractions. This enables product and process designs from biomass assays for a net-zero circular bioeconomy.

Jhuma is a world-leading specialist in life cycle assessment (LCA) (ISO14040-44), carbon footprint (ISO14064-65), and life cycle sustainability assessment (LCSA) (ISO26000) comprising (environmental) LCA, (economic) life cycle costing (LCC) and social LCA. Jhuma with her team created Software: TESARREC™ UK00003321198 to design and evaluate renewable, waste and greenhouse gas capture and sequestration strategies based on their optimal or standard technical, economic, environmental and social life cycle performances for regulators and designers. Her team has also developed a net-zero power system optimisation model. It includes all renewable energy system models, including solar and wind. She developed novel standards for bioenergy LCSA, renewable energy LCSA, renewable energy LCA, renewable energy sustainability indicators, local renewable energy generation analysis, and energy system optimisation for net-zero electricity. Jhuma drives innovation across the scale and all dimensions through effective multi-scale multi-dimensional approaches, social sciences, SLCA, Economic, Environmental, and Safety Performances, safety, LCA with ecosystem, health, monetization, and soil CO2 sequestration impacts, LCSA, Fuzzy set theory and Monte Carlo simulation and multi-criteria decision support. Her research also integrates earth observation for sustainability monitoring, reporting and verification, GIS for bioenergy evaluation, global biomass availability database, and upstream pre-processing systems, including milling operations and densified fuel production. Jhuma’s methodologies demonstrate practical problem solving using ISO standards: ISO14040-44, ISO14064-65, ISO23247 and ISO26000 for holistic whole system sustainability, tackling global grand challenges, net-zero/decarbonisation, circular economy, resource security/efficiency, and sustainability. She systematically evaluates and maximises the environmental, economic, and social performances throughout the complete life cycle of products and services.

Engineering Biology is another domain Jhuma is making a remarkable contribution to up-scaling and sustainability. Her research is at the core of sustainable net-zero pathways through more efficient, cost-effective, environmentally friendly, and socially responsible product and process innovations. Through a significant funding contribution and a long-standing track record, she is helping the discipline by up-scaling bioprocesses for various resource recoveries from waste streams. The recovered resources are organic materials, acetic acid, formic acid, Dewatered sludge via Fenton process and all volatile fatty acids, as well as metals such as chromium, copper, zinc, functional magnetite nanoparticles, natural iron minerals, lithium, etc. She engages in microbial fuel cell and microbial electrosynthesis research using CFD simulations and experimentation, CFD simulations, and dynamic simulation.

Another significant invention includes carbon dioxide reusing chemical production and process configuration options, e.g., via microbial electrosynthesis, polygeneration, decarbonised energy generation and graphical carbon dioxide minimisation. She with several industries is producing the world’s first commercial surfactant with carbon dioxide reuse. She published the first-ever CO2-to-surfactant synthesis LCA and TEA studies.

Jhuma's bioethanol works include LCA, bioethanol pinch, commercial arabinoxylan co-production with bioethanol, arabinoxylan extraction from bran, sago bioethanol, and all biomass evaluations in Mexico for biorefining into bioethanol.

Jhuma's biodiesel research consists of the first hydrotalcite-based heterogeneous catalytic biodiesel production, heterogeneously catalysed transesterification reaction process, multi-scale simulation, and process intensification. Her other multi-scale simulation works include metabolic pathways and metabolic productivity optimisation. Biorefinery examples include dihydroxyacetone and succinic acid production from glycerol co-produced with biodiesel, and from bread waste and sustainable valorisation of bread waste.

Jhuma's invention includes novel high-efficiency bioenergy schematics, gasification-based, IGCC-based, biogas/biomethane-based, Bottled Biogas for Clean Cooking, combining intensifying and optimising fuel cells, integrated gasification fuel cell (IGFC) and integrated gasification combined cycle (IGCC) systems, solid oxide fuel cell and gas turbine hybrid and via metabolic hydrogen production.

Jhuma's thermochemical biorefineries include Fischer-Tropsch and methanol syntheses, sustainable aviation fuel synthesis, co-processing into biojet fuel and green diesel, lignin pyrolysis, and hydrogen production process intensification.

Jhuma developed a new standard method, value analysis, which has been widely applied, for example, to synthesise arabinoxylan co-producing biorefinery configurations for maximum economic margin. Her value analysis methodology led to multi-dimensional economic value and environmental impact analysis. The method can analyse economic value and cost and environmental credit and debit differentially for all streams in a complex process network, thus helping in the diagnosis of profitable or non-profitable and environmentally benign or polluting streams, read here. The analysis helps in rejecting the non-profitable/polluting streams and replacing them with novel, profitable and benign streams (thus, production pathways, or routes). This graph theory-based computational value analysis method includes multi-dimensions to consider and balance tradeoffs. It lowers the computational power in optimising a complex flowsheet with the best tradeoffs between various sustainability criteria, excerpted here.

Jhuma supervised 30+ PhD graduates and 40+ postdoctoral researchers who after successful completion settled in academics as well as the top-level decision-making positions in non-academic organisations. Many PhD graduates were industrially funded, (e.g., with Johnson Matthey, Unilever, TWI Ltd., WRAP, National Composite Centre, Nestle, Recycling Technologies, 3M, National Physical Laboratory and Network Rail, etc.), and e.g., the Process Integration Industrial Consortium, at The University of Manchester. She is currently supervising 8 PhDs including 2 fully funded by the industry (Unilever (Environmental Rating Ecolabeling of food and consumer products) and Johnson Matthey (circular economy for platinum group metals for the hydrogen economy)) and 9 Research Fellows.

Jhuma's research co-delivered with the industry, new standards, policies and methodologies with novel significant scientific evidence generation, such as Environmental Rating Ecolabeling, product carbon footprint or PCF, life cycle inventory analyses for multi-national companies, net-zero system optimisation, sustainability indicators for renewable energy, energy integration for complex factories, energy efficiency, energy reduction and enhanced process performance, energy reduction in osmotically-assisted reverse osmosis, asset management, industrial oven optimisation and sustainability, clothing sector circular economy business model, carbon fibre-reinforced composite materials in the aviation industry, resource recovery from waste and gasification integration into industrial facilities. She regularly advises the industry, SMEs and UKRI and formally holds an Advisory position with BBSRC: Advanced Manufacturing & Clean Growth. She is a full Peer-review College Member of EPSRC. She regularly serves the UKRI funding decision-making panels. She led SMEs in novel trade-secret biopolymer-based plastics formulations. In another invention, she led an SME in clinical plastics circular economy configurations, optimisation, and economic and environmental value analysis. She helped another SME in mixed plastic waste remanufacturing. She conducted the first comprehensive LCA for battery energy storage systems with an SME. She is currently leading an SME in the creation of a carbon footprint calculator for the visitor economy. She led another SME creating a sustainable biomass availability database.

Jhuma currently contributes to £50M+ UKRI grants including as PI. She is a leading educator of LCA/LCSA and biorefining/bioeconomy. Jhuma has been an External Examiner of the MSc Sustainable Chemical Engineering courses at the Universities of Newcastle and Bath. Jhuma has created a global community of professionals and practitioners – the Institution of Biorefinery Engineers, Scientists and Technologists (IBEST), established in 2015. As the IBEST Founder, Jhuma led significant international conferences and workshops through prestigious international Newton funds as PI with Mexico, Malaysia and India. Through the Newton Funding Scheme (£1M+), Jhuma helps the international community of early career researchers to grow professionally.

Resources

This is a video by James Smith and Dr Henry Yu from the Multifunctional and Sustainable Structures group. James takes us through the current methods for recycling carbon composites and the challenges associated with each one. For more information about the group can be found here.