Sustainable water and wastewater processing

Our activities focus on addressing the global water-energy nexus challenges including developing innovative methods for sustainable desalination, wastewater processing and water recycling to provide clean water to address the rising global pressure for fresh water supply, energy recovery from wet waste or wastewater, and wastewater treatment process synthesis and real-time optimisation and control.

Facilities

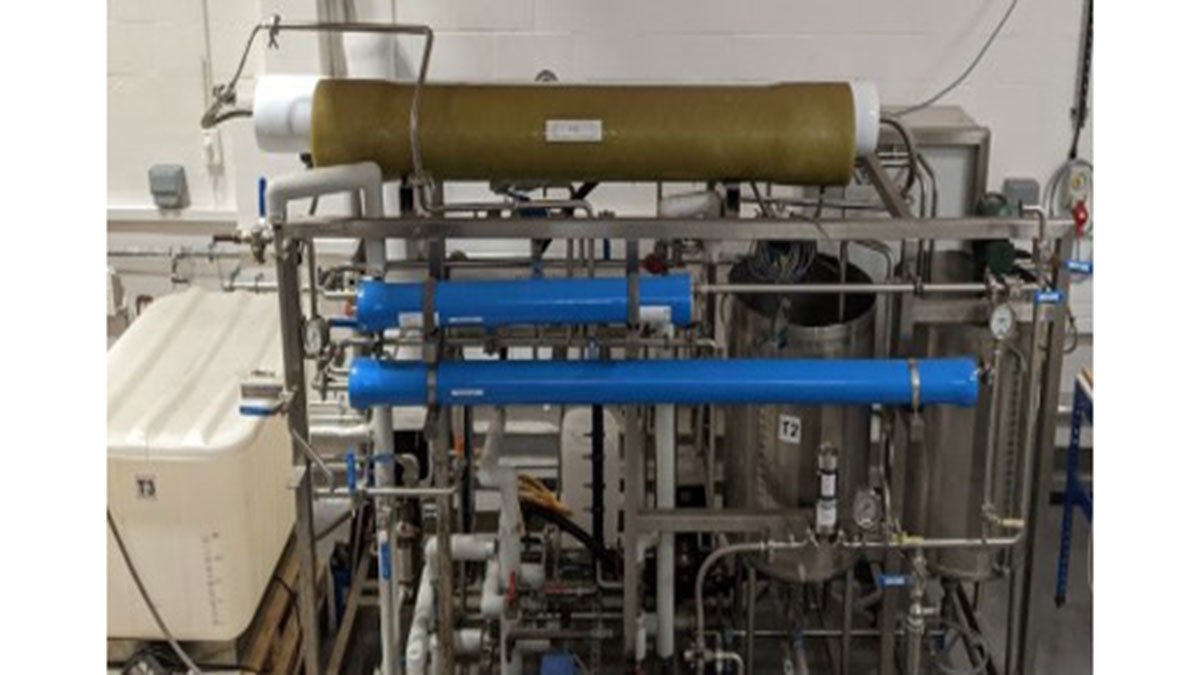

Pilot scale water and wastewater treatment and biomass processing

- FO/NF/RO membrane filtration systems

- 20kHz horn capable of flow through, treatment at high pressure and temperature for biomass.

Techno-economic and life cycle assessment

- SimaPro

- SuperPro Designer.

Analysis of scaling/precipitation

- PHREEQC program.

Techno-economic and real-time optimisation

- General algebraic modeling system (GAMS).

Bioreactor modelling

- COMSOL software

- MATLAB platform.

Energy labs

- Bench top water-splitting setup for hydrogen production

- Microbial electrosynthesis system (MES) for waste-water treatment.

Analytical instruments

- Inductively coupled plasma - optical emission spectrometry (ICP-OES)

- Nanoparticle tracking analysis (NTA)

- Total organic carbon (TOC)

- High-performance liquid chromatography (HPLC)

- Ultraviolet-visible spectroscopy (UV-VIS)

- Low light camera

- Data colour spectrophotometer

- Potentiostat/galvanostat electrochemical impedance spectroscopy analyser

- Conductometer.

Bench scale water and wastewater and biomass treatment

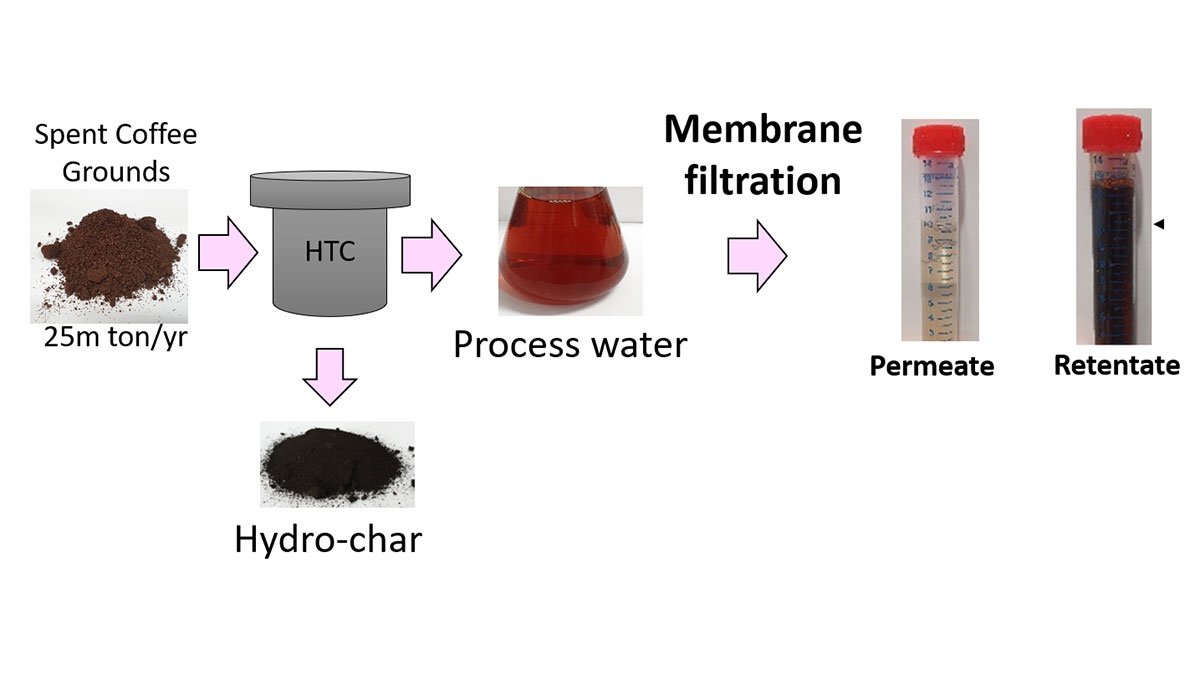

- Hydrothermal carbonisation reactor owned by Antaco

- UF/NF/RO/FO membrane filtration systems

- Multifrequency ultrasound processing systems

- Biological digesters

- Sludge and waste water treatment.

Collaborations

Academic institutions

Projects

Completed projects

Start date: 2017

End date: 2018

Meet the team

Academic staff

Dr Bahman Amini Horri

Associate Professor of Chemical Engineering and Sustainable Energy; Leader of MSc Sustainable Energy; Fellow at the Institute for Sustainability

Dr Madeleine Bussemaker

Associate Professor in Chemical Engineering

Dr Franjo Cecelja

Reader

Dr Ralph Chadeesingh

Senior Teaching Fellow in Chemical Process Engineering

Dr Melis Duyar

Senior Lecturer in Chemical and Process Engineering

Dr Siddharth Gadkari

Lecturer in Chemical Process Engineering

Professor Judy Lee

Professor in Chemical and Process Engineering

Dr Michael Short

Associate Professor of Process Systems Engineering

Professor Rex Thorpe

Professor of Chemical Engineering

Dr Dimitrios Tsaoulidis

Senior Lecturer in Chemical Engineering

Postgraduate research students

Read completed dissertations by our past students:

- Odour treatment in sewage treatment works by Behzad Haji Mirza Beigi

- Unlocking the full energy potential of sewage sludge by Nick Mills

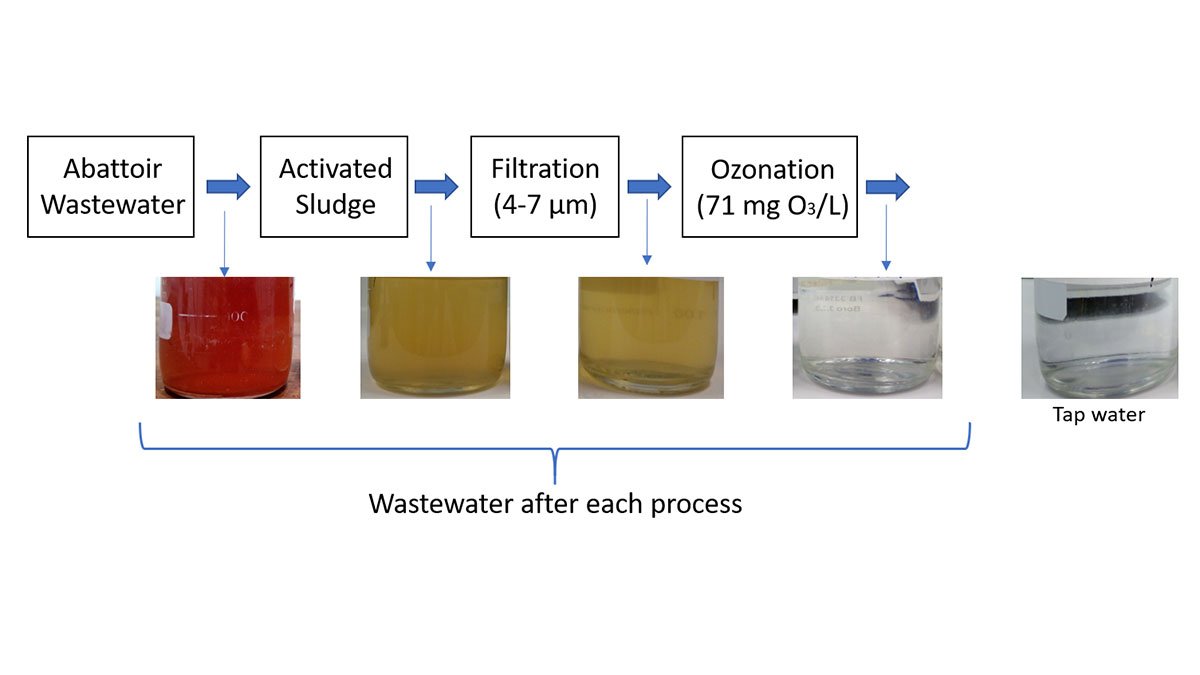

- Advanced oxidation processes for the treatment of real slaughterhouse wastewater after a biological treatment by Pello Alfonso-Muniozguren

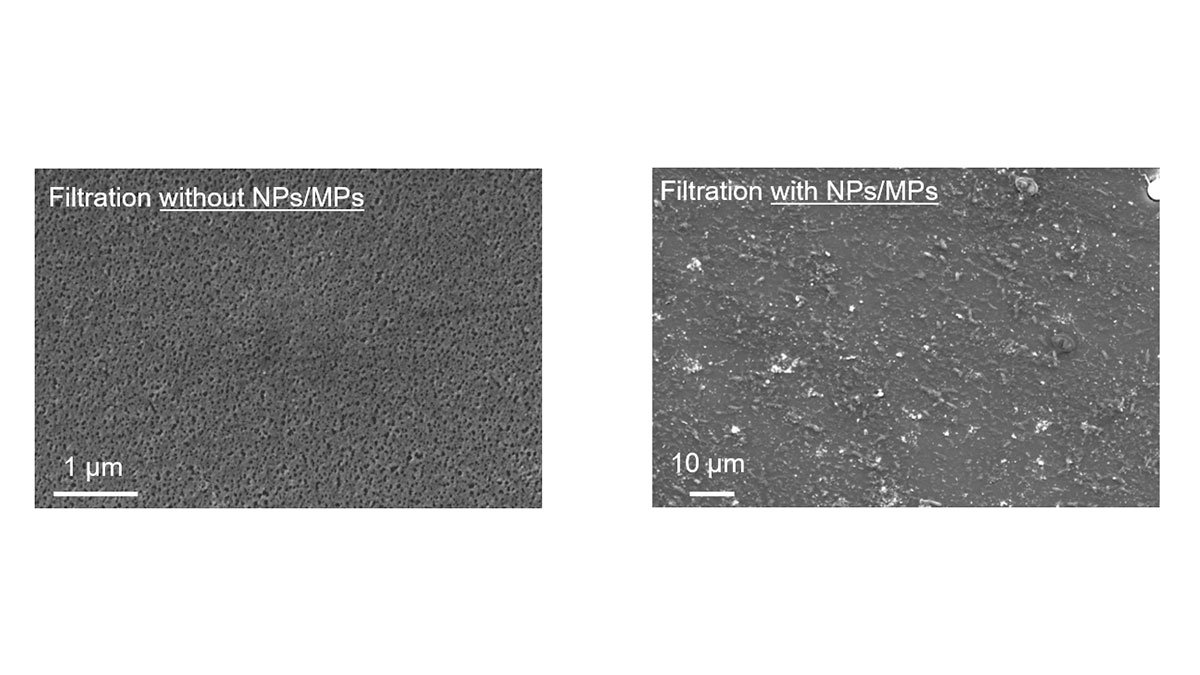

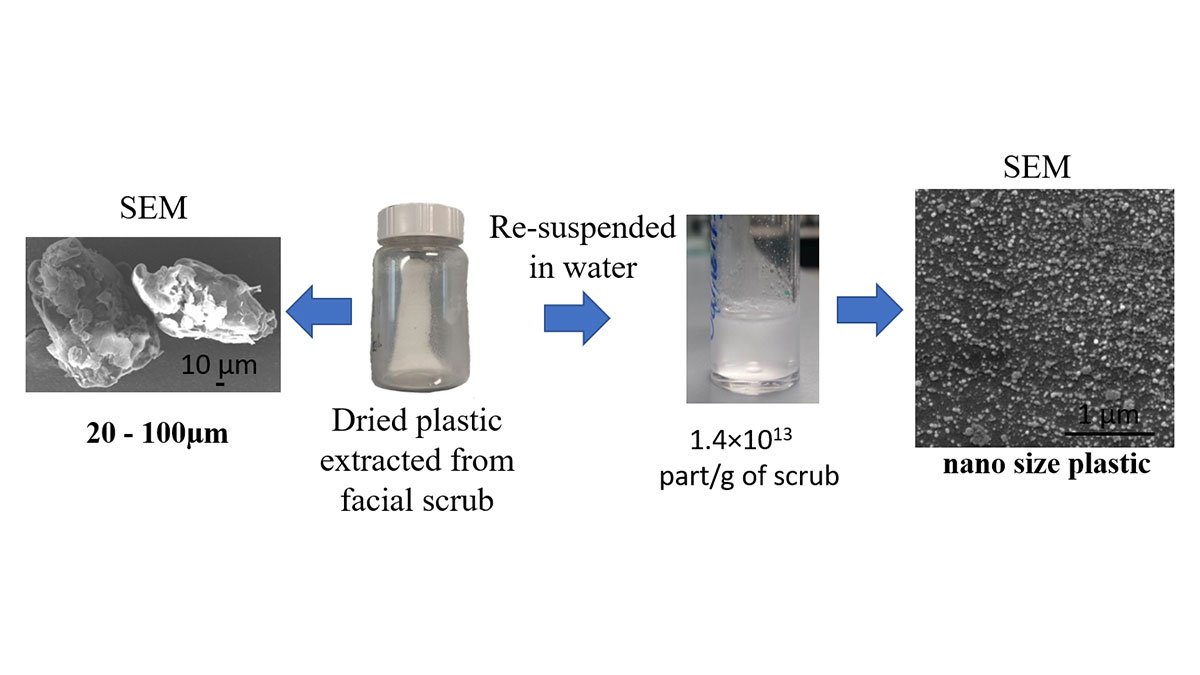

- Membrane fouling by nano/microplastics: Origin mechanisms and mitigation strategies by Marie Clemence Enfrin.

Meshkat Dolat

Project: Optimisation and system design for bespoke dual function materials for direct air carbon capture and utilisation

Ros Fomin

Project: Fouling behaviour of a membrane bioreactor system and the impact of different cleaning operations

Cyril Hachemi

Project: Comprehensive understanding of the impact of microplastics on membrane bioreactors

Mustapha Hamdan

Postgraduate Research Student

Junbin Huang

Project: CO2 reduction through microbial electrolysis system and chemicals upgrading

Om Sabnis

MSc summer researcher

Anna Salvian

Project: Development of microbial self-powered biosensor for water quality monitoring

Dr Tim Sidnell

Project: Ultrasonic degradation of per- and polyfluoroalkyl substances

Maano Tshimange

Project: Mining of phosphorus in wastewater using forward-osmosis membrane system

Dr Mehrdad Zare

Project: Ultrasonic remediation of pharmaceutical emerging contaminants (ECs) in water/wastewater